Maybe this helps: https://www.speedste...&comment=131604

(its more about the OBD Pro Setup)

If you mount the System behind the seats, you can reach all cables from the engine bay. But you can mount it where ever you want.

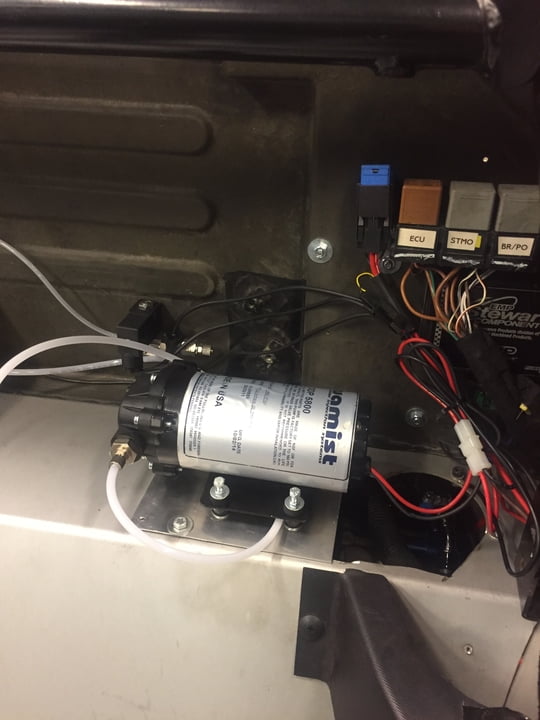

The high pressure water pump has to sit below the water tank because it cant suck water. If not possitble you can install an additional pump (the golden thing on my picture) to provide the water to the high pressure pump.

You will get the best cooling results when you mount two parallel nozzles behind the laminovas.

You have to calculate the nozzle size depending on your boost and desired water mixture.

If you know the size of your fuel nozzles you have to multiply them by 4 and by the % you want to have water added.

For Example: My fuel nozzles are 4 x 680 cc/min = 2720 cc/min

I want to inject pure water so the mixture has to be 10-15%, lets say 12% -> 2720 x 0,12 = 326 cc/m

My boost is ~1,5 bar = 14,5 psi

Pressure difference over the nozzle would be pressure of waterpump ( its always 150 psi) minus boost pressure -> 150 psi - 14,5 psi = 135,5 psi

Now you look into the table and search for the best nozzle that provides ~326 cc/min @ 135,5 psi

As we want to have two nozzles in parallel, you must look for 326 cc/min / 2 = 163 cc/min @ 135,5 psi

In this case you would end up somewhere between the yellow and the green line, but closer to the yellow line.

You must choose one of both. Do you wan tto have more or less water ? Lets calculate with both nozzles how the water / fuel ratio will be:

Yellow Nozzle: 150 cc/min @ 135 psi (in total 300 cc/min)

Blue Nozzle : 200 cc/min @ 135 psi (in total 400 cc/min)

Devide that thorugh the max fuel flow and you get the ratio.

Our max fuel flow is 4x 680 cc/min = 2720 cc/min

Yellow Nozzle: 300 / 2720 = 0,110 -> 11% water

Blue Nozzle: 400 / 2720 = 0,147 -> 14,7% water

You must now choose one of these

You can calculate it the same way with your own boost and fuel nozzle sizes.

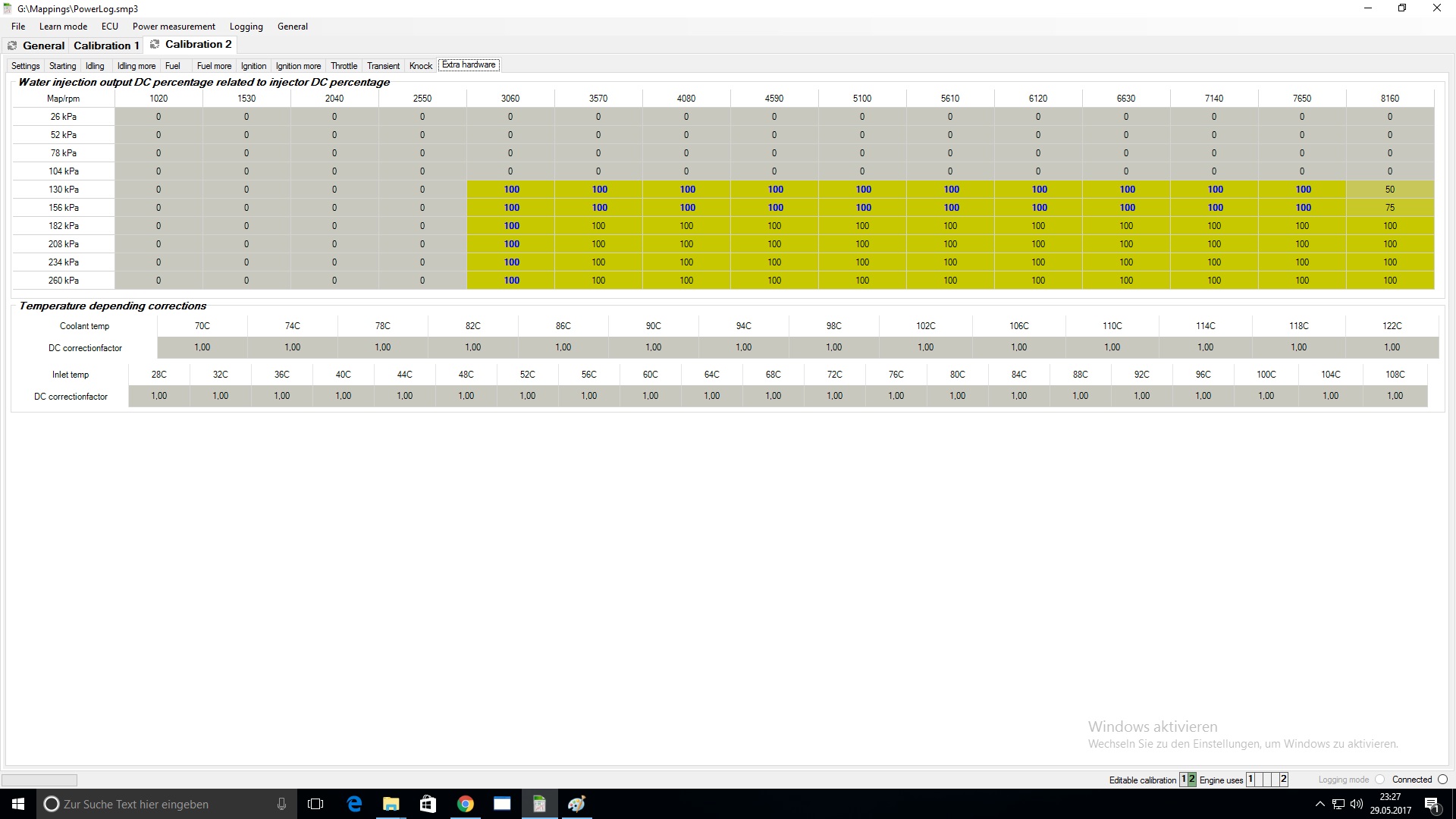

I would always take the bigger nozzle for future upgrade and if you use OBD Tuner pro you can minimize the water flow by multiplying the IDC. (watch at my link)

More Infos for setting up the water IDC in OBD Tuner PRO can be found here (german) https://www.speedste...&comment=132201

Edited by FabianG, 09 December 2019 - 01:26 PM.