One thing led to another and I decided to reduce some static and roating mass by looking at alternators (http://www.vx220.org...00a-alternator/ )

That thing led to another thing, and in the photos below you will see how to mount a Corsa 1.3 CDTI 90A alternator.

I am aware this is not as far-out as buying a small Denso racing unit, or a 50A off an old Daihatsu etc., and that will be for another day, but you can get these alternators on ebay for £20, so I felt it was worth the try.

This is a Denso manufactured unit and it seems that 1.2 petrol Corsas had a 70A version with more conventional radial mounts. It can be made to fit and they are around £20 on ebay and I did get one to try, but I had another idea.

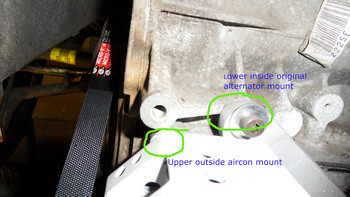

I had seen a member on here had relocated his alternator to the aircon location to fit a supercharger. While he may (or may not) have done it for expediency in supercharging, it has the nice effect of putting a roughly 5kg mass around 130mm lower in the chassis. I will also show that it can also allow you to remove the heavy pulley tensioner and have a direct belt.

There is one major downside to this method - you need to modify the unused lower aircon on the sump (see below).

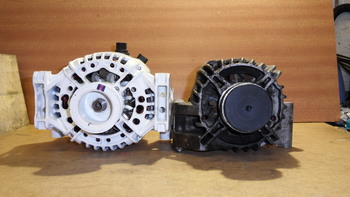

First up is to weight the new part:

5.2kg. That includes a rather heavy one-way alternator pulley which with only the crank driving the alternator I elected to swap for a new lighter aluminium one.

This is the part:

as mentioned it is in the same family as the 1.2 Corsa 70A.

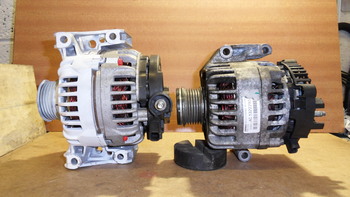

Here are the comparisons with the z22se 100A unit:

The z22se 100A unit is just shy of 138mm across (there is double parallax error in the photo, but thats the measurement):

The CDTi 90A unit is 120mm across (slightly less parralax error in this shot)

If you are not familiar with OAPs/clutched pulleys they need a special 33 spline tool to get them off. £4 on ebay.

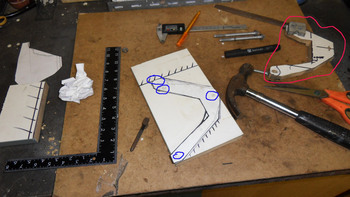

What is now going to be shown is mounting a 1.3 CDTi alternator in the position of the aircon pump that VX220s don't have (it was maybe an option - I do not know).

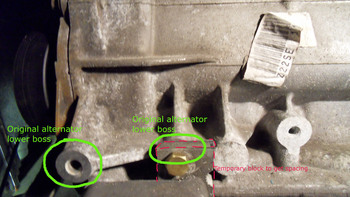

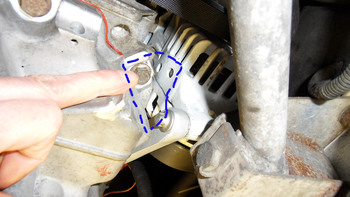

Modification 1 - Remove the dowel and grind the upper, outer alternator mount flush to the webbing:

This picture shows the original 100A alternator mountinG bosses:

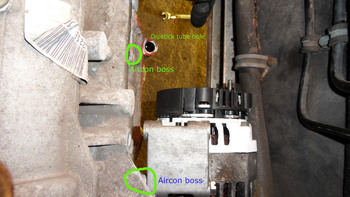

These are the aircon bosses we will pick up on to mount the 90A: