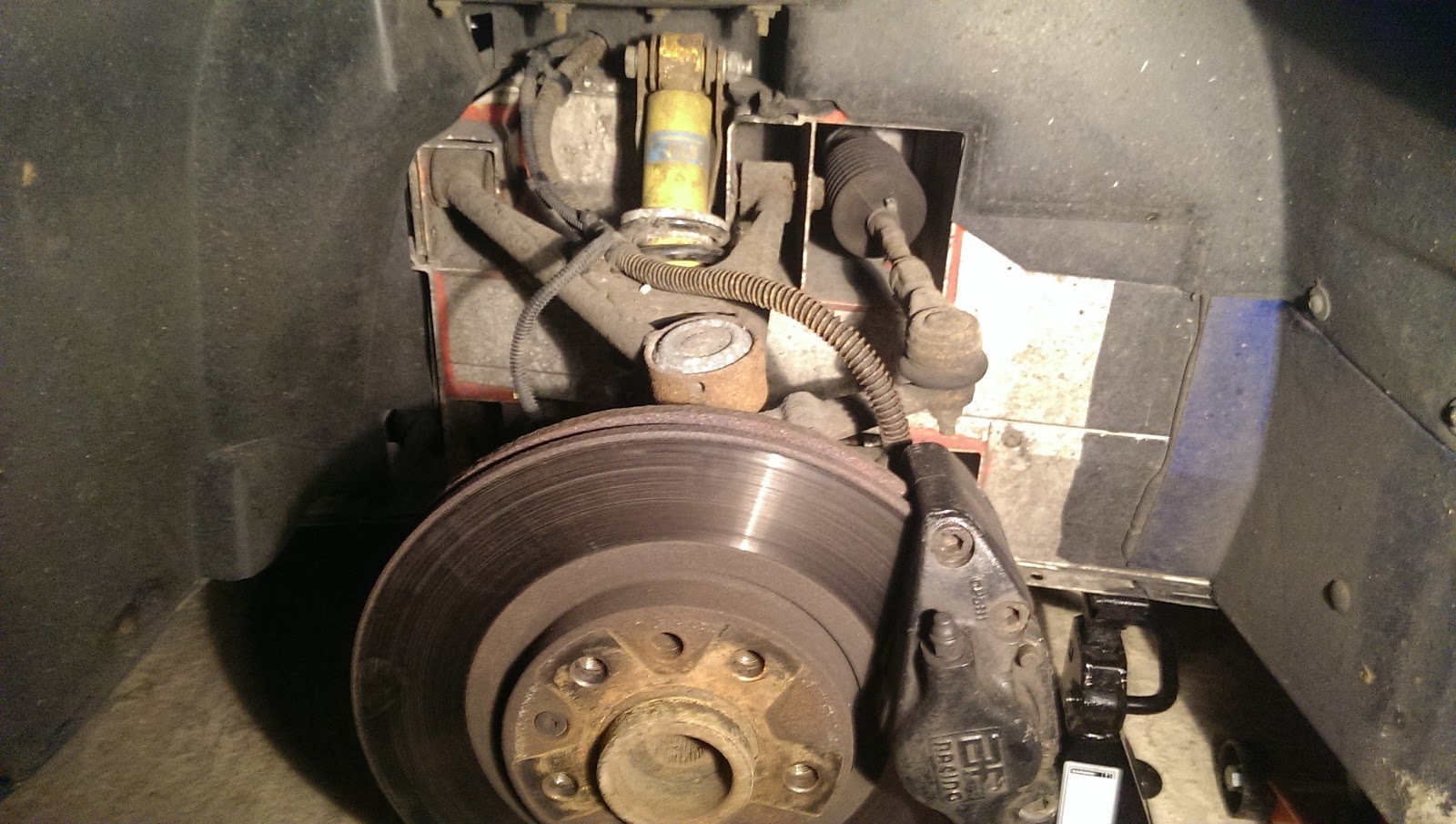

- Replace worn, grindy old disks with new Camskill discs and Mintex M1155 pads deal. Flush through new brake fluid. Already got parts and will do this job before MOT.

- Remove all suspension parts, probably using own bodyweight in Plusgas

, remove rust by DIY electrolysis, paint with POR15.

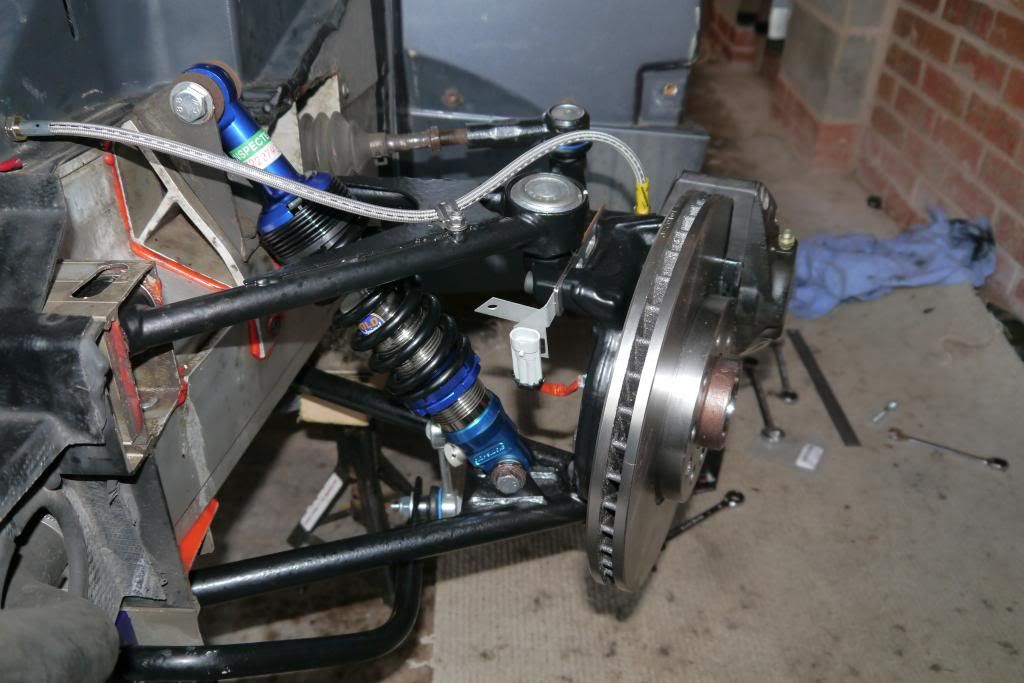

, remove rust by DIY electrolysis, paint with POR15. - Refresh with Seriously Lotus kit incl. OEM-style bushes and Nitron Street Series dampers.

- Replace toe links at same time?

- May replace all wheel bearings at the same time... not sure yet.

- ARB bushes are dry and cracked. May consider Elise Parts uprated 1" ARB if doing bushes.

- Driver seat bolster is torn so I'll get the seats recovered. May try removing some of the arse padding for a lower driving position. Remove whatever detritus is rattling under seats.

- Replace footwell mats. My left heel sometimes gets caught in the seam around the edge of the triangular raised bits which can be scary when going full pelt.

- Repaint brake calipers.

- Remove then clean up steering wheel, remove and respray steering wheel centre/airbag. Treat leather. Restitch wheel with blue thread

.

. - New gear knob, handbrake sleeve, gaitors.

- Replace carbon fibre sills and window winders with OEM ones.

- Respray all interior silver plastic trim, keeping colour as similar to OEM as possible.

- Respray exterior black grilles, which are faded/chipped.

- Investigate mystery object rattling in passenger door and fix both sides window rattles.

- Fix heater knob which is stuck in hot position. Cover vents with wife's undergarments if not already covered by stranger's wife's undergarments.

- Correct poorly aligned Milltek backbox, investigate rattle from cold (busted baffle?), re-align heat shield and replace scruffy exhaust grille...

Edited by GaryK, 03 August 2015 - 01:05 PM.