Hi guys,

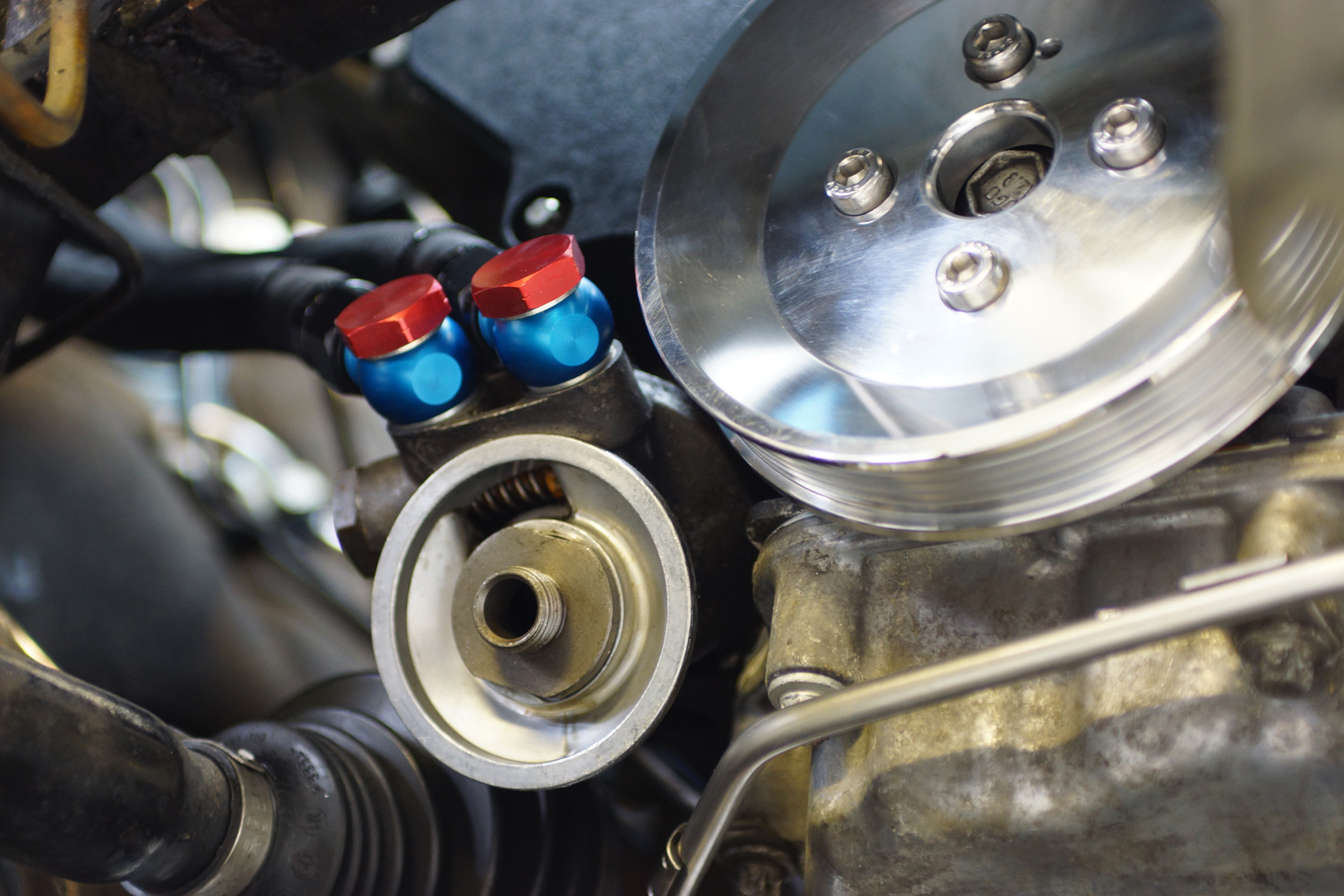

Does anyone know which way the oil flows through the VXT water/oil heat exhange matrix? In other words, does the hot oil coming from the engine pump enter the left end or the right end (when looking at it from the boot)?

The reason I ask is that I am thinking of drilling and tapping an oil sender into one of those huge banjo bolts that feed the heat exhange matrix. Natually I'd like to put the sensor on the inlet (to see the temps before they oil is cooled (not that the cooler does a huge amount I am sure!)).

Thanks in advance.

N+N.

Edited by Nev, 30 March 2016 - 11:27 AM.