Iram/mbr Vxt Project . That Will Do Wont!

#61

Posted 16 April 2019 - 07:47 AM

#62

Posted 16 April 2019 - 07:48 AM

#63

Posted 16 April 2019 - 07:54 AM

#64

Posted 18 April 2019 - 10:44 AM

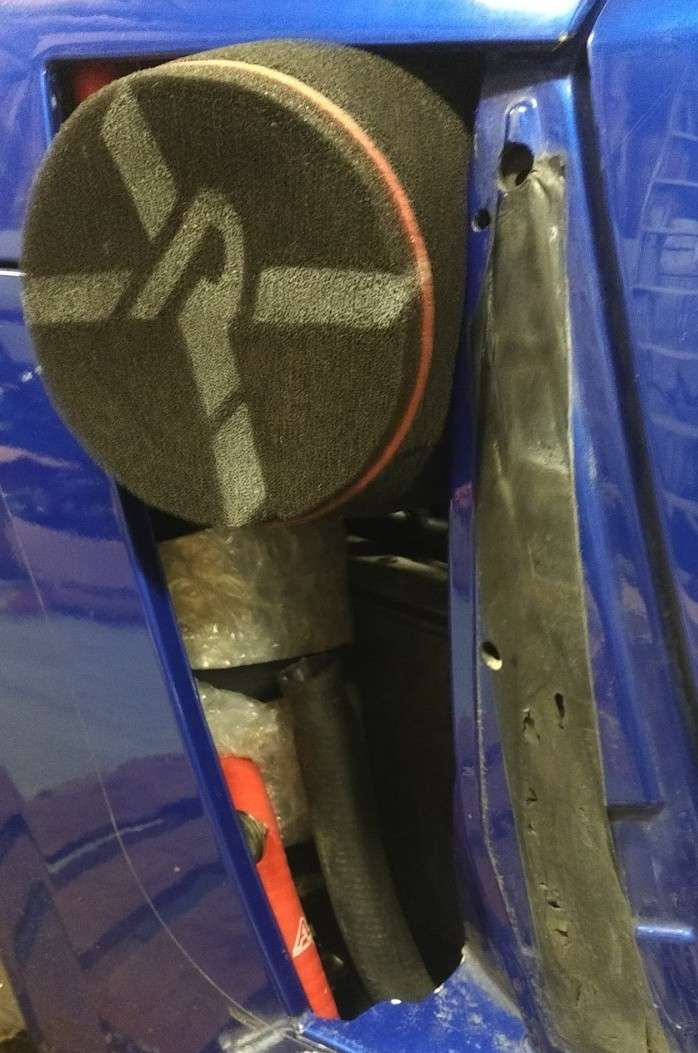

additional cone added to increase the air filter volume worked very well and paid dividends! all on the far side of the car! boxed in as to not draw in any engine bay air and pulls from the air intake scoops! which has a large area after removing the pro alloy to pwr charge cooler!

#65

Posted 18 April 2019 - 10:46 AM

#66

Posted 19 April 2019 - 04:28 PM

ditch the 4 bolt flange from exhaust manifold to turbo and weld on direct and angle the external waste gate pipe to a v configuration! no more flange gaskets to change! will re coat at some point in the future! in the winter!

ditch the 4 bolt flange from exhaust manifold to turbo and weld on direct and angle the external waste gate pipe to a v configuration! no more flange gaskets to change! will re coat at some point in the future! in the winter!

#67

Posted 21 April 2019 - 01:47 PM

out with the pro alloy charge cooler after it failed due to expansion and in with the pwr fits in snug also fitted sensors to measure the intake and flow water temps

out with the pro alloy charge cooler after it failed due to expansion and in with the pwr fits in snug also fitted sensors to measure the intake and flow water temps

#68

Posted 21 April 2019 - 01:49 PM

#69

Posted 22 April 2019 - 10:04 AM

after a few times of gasket blows on the turbo to manifold! decided to cut and welded on a v-band to the exhaust manifold and also v-banded from downpipe to exhaust ! a lot more sensible!

so i decided to make a 3" exhaust system to see if it made any difference what so ever! so made one with a simpson muffler and welded stainless !

cut and angled the T to make a V joint from manifold to external waste gate to make flow better

put it on the dyno! result minimal change if any power coming in 500 rpm earlier! simpson muffler sounds great though!

while on dyno noticed it was sucking in the air cone filter (450hp rating) so removed the filter to see if there was a difference ! there was slight so decided to make a two cone into one pipe to turbo configuration which did the job!

run the car for a few months and then exposed the limits of the pro alloy charger that blew out like a blow fish! so from that point looked into new avenues and went for a PWR charge cooler 650hp ish that fits in the offside side of the car a lot easier and takes up less room and allows more air space for the filter intake!

increase pipework from 55mm to 75mm all round from turbo to charge to intake manifold and this is where the significant increase came from in performance! with out any mapping change just a straight run the gain was 17hp /4 ftlbs

will do a few map mods/boost with matt B and see if further improvements can be made!

next mod is the introduction of traction control as you need to feed the throttle

iram

I think you've discovered the fundamental truth about engines, it's all about the breathing. They are just an air pump, the easier you make it for air to go in and to come out, the more powerful (and efficient) they become.

I did all of what you have (and a bit more besides) about 8 years ago and also got great results as well. My engine uses just 11 PSI of boost (same as the OEM VXT) yet makes 140% more power, mainly due to efficiencies of air flow.

You must be on the cusp of where a 3.5" diameter exhaust might help too.

Edited by Nev, 22 April 2019 - 10:06 AM.

#70

Posted 24 April 2019 - 06:47 PM

#71

Posted 25 April 2019 - 05:50 PM

I had a CS/Klassen map for a year or so, which was woeful due to nasty onset of boost (and caused suspected bore wash).

Since then I've had an after market ECU installed which has excellent torque characteristics (in low torque mode). I can also flick a switch on the dash to put it into high torque mode, or set boost limits with a laptop anywhere between those two points. All in all it's modern enough for me.

The only "issue" with mine is that due to low CR and moderate sized turbo I have to spin the engine up quite a bit to get power. But if pedalling hard once I'm in the 4000 to 8000 RPM range it's easy to make progress.

Edited by Nev, 25 April 2019 - 05:51 PM.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users