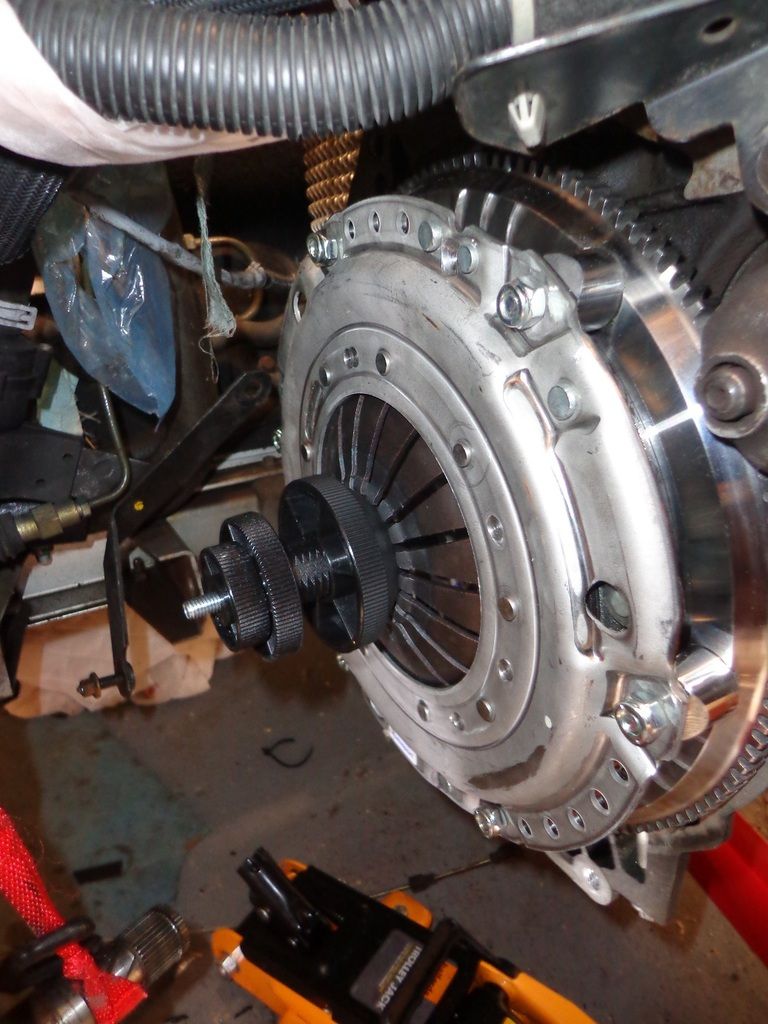

Evening all, does anybody have any tips for the PITA job that is refitting the F23 gearbox? I've changed the clutch and flywheel (performance Courtney items) but the gearbox refitting is proving a real pain. I've been close but I cannot seem to align the gearbox input shaft (despite rotating it with a screw driver) to the engine. I've dropped the gearbox it back to the floor to form my next plan of attack. I currently have the engine on a jack and the gear box on a hoist (two ratchet straps so I can alter the angle). I tried lowering the engine to create a different angle for the gearbox but no joy so far. I've been following Nev's excellent guide but this has got me stumped. Photo's available if that would help.