Let me post everything before posting comments!

Here’s my quick method: -

Before removing or changing anything, get a length of wide, planed timber as shown in the picture. By ensuring that the wood touches both the front and the back edge of the rear rim, you can now measure to a datum-point at the front of the car. The best place for this is the centre of the front wheel, as this is a point that matters when it comes to steering-geometry.

You’ll see from the second picture, that I’ve had to attach to little blocks of wood to the edge of the plank to ensure that the rim only touches at the front and back rim-edge. I also got my son to put some pressure on the plank to make sure of good contact with the rim.

You now take a reading from the plank–edge to the centre of the front wheel, using a steel-measure. Get the idea?

You only need to do the side that you’re changing the track-control arm on, but I did both for interest. Oh, and stand the plank on a pile of bricks as per the picture – don’t try to just hold it in place. Jiggle the plank gently to ensure that it overcomes any friction between the plank and bricks.

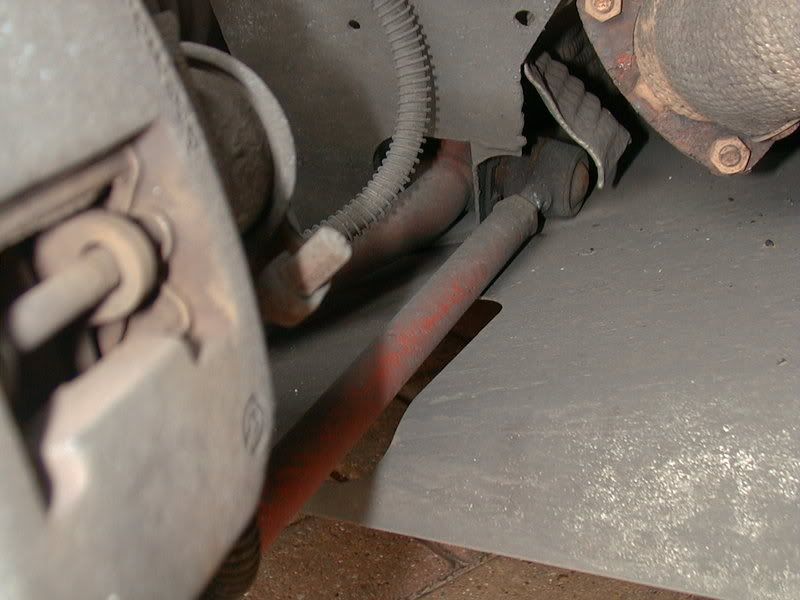

Here’s the old arm in-situ. You can see why the inner ball-joint dries out – it’s very close to the exhaust.

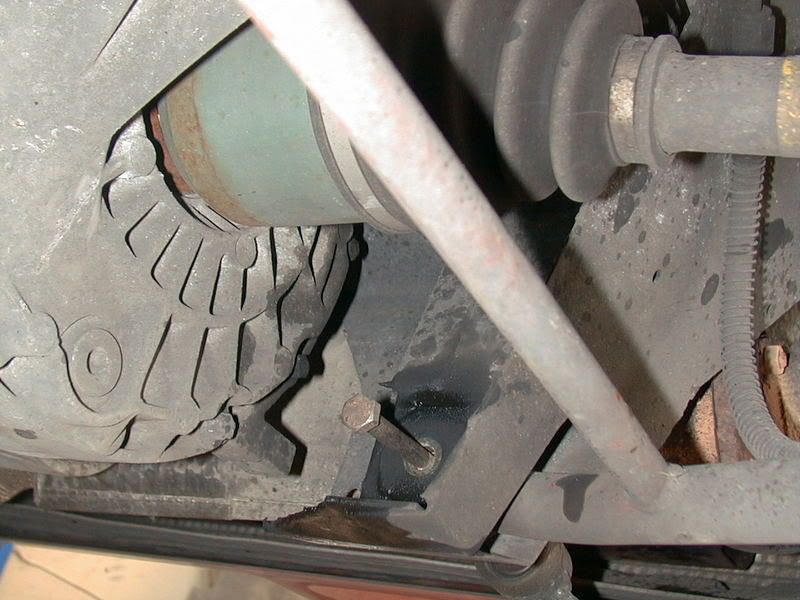

Here’s the outer-end. You can see the outer ball-joint connected to a trailing-arm part of the hub-casting.

Right. Now remove the undertrays.

And make sure the car is supported properly – not just a jack. You’ll be lying under the car for some of it…

Remove the brake-calliper – which is as per the instructions for changing the brake-pads.

And remove the actual brake-disk. It’s only held on with a single allan-screw.

Time to remove the old track-control arm. Use some WD40 to ensure things come off easier. Undo the nut on the end of the ball-joint stem. This stem goes through the back of the chassis, through the rear joint of the lower wishbone, and out the front-side of the chassis. Tap the ball-joint out by using an old bolt of almost the same diameter. That way, the old bolt will keep the wish-bone located.

Then remove the outer ball-joint making note of where the washers and spacers go. The old track-control arm can then be fully removed from the car.

Now to fit the new arm. Screw the new ball-joints in and out of the new arm to make it roughly the same length as the old one – but don’t worry too much about accuracy. Also note that one ball-joint has a left-hand thread and the other has a normal right-hand thread – you’ll understand why later on.

Fit the new arm to the car in the time-honoured way. Note: - the two flats on the body of the inner ball-joint locate on positioners on the chassis to stop it turning. Do the ball-joint mountings up tight.

Put the brake disk and callipers back on and refit the wheel without putting all the under-tray stuff on just yet. Lower the car back onto the ground.

The reason for the left-hand thread and right-hand thread on the two ball-joints, is that if you now rotate the track-control arm in one direction the shaft will grow in length. If you turn it in the other direction then it’ll get shorter. You’ll be surprised how many people don’t suss this out, and try adjusting the length by turning one ball-joint a full rotation.

Get the plank and bricks out and re-adjust the tracking of the wheel.

When finshed, lock the locking-nuts up by using two spanners.

Now you can either put the undertray back on, or go and do the other side.

The usual warning. This is intended as a guide only, and if you don’t have the ability, then don’t attempt this. On a grade of 1-to-10 for ease of doing, I’d rate it pretty easy if you take the time and car. It took my son Ben and I about two hours to do one side.

All done!!!!

Steve