Boost Solenoid/wastegate Interaction

#1

Posted 24 October 2009 - 10:18 PM

#2

Posted 25 October 2009 - 07:35 AM

#3

Posted 25 October 2009 - 09:41 AM

#4

Posted 25 October 2009 - 09:58 AM

Edited by Nev, 25 October 2009 - 09:59 AM.

#5

Posted 25 October 2009 - 12:26 PM

#6

Posted 25 October 2009 - 06:24 PM

Edited by colgy, 25 October 2009 - 07:16 PM.

#7

Posted 26 October 2009 - 06:34 PM

#8

Posted 26 October 2009 - 10:03 PM

Changeing the winding nuts on the actuator without approriate fueling changes is dangerous, especially if you are increasing boost by so much. You are almost certainly running very lean AFR (which may explain why you are getting less power) and will lead to burnt out pistons with holes in them, possible melted exhaust valves and a very expensive bill...

actuator controls boost/speed of turbine and has chuff all to do with AFR

#9

Posted 27 October 2009 - 09:21 AM

#10

Posted 27 October 2009 - 09:35 AM

#11

Posted 27 October 2009 - 09:41 AM

Edited by Duncan VXR, 27 October 2009 - 09:53 AM.

#12

Posted 27 October 2009 - 09:41 AM

Edited by Duncan VXR, 27 October 2009 - 09:53 AM.

#13

Posted 27 October 2009 - 09:52 AM

#14

Posted 28 October 2009 - 12:06 AM

Cheeky, I'm guessing from some of your other posts that you know a bit about this

How does the solenoid on the turbo actually control the actuator?

lol - i spent alot of time figuring out what the rear solenoid does as the chatter does my head in! (basically 2 inputs, FPR/vacuum > output to recirc - the ecu swaps the solenoid FPR input to the vacuum when needed to "hit" or speed the recirc opening (when it detects throttle closing)

Alas, i havent had a real need to pull the actuator/solenoid/pipes apart

#15

Posted 28 October 2009 - 12:46 AM

#16

Posted 28 October 2009 - 12:55 AM

you could see the boost gauge wave when mine went weak and was only lower down where the penny was being pushed by the higher boost pressurePossibly the spring gone 'weak' as people say, although the turbo was replaced 10k miles ago so maybe the fornt BCS....

24 is bang on. Not convinced the rear BCS is your problemJust can't hold more than 9.5 psi after that though, I've got my fingers crossed that a new rear BCS might do something......

I have a vacuum of 24 in hg, all the pipework looks secure, boost side looks ok, but then how do you pressure test it?

spot onThink I'm starting to get my head around it - think the vacuum box there to help the re-circ valve open more quickly/postively?

#17

Posted 28 October 2009 - 07:01 PM

#18

Posted 29 October 2009 - 02:50 AM

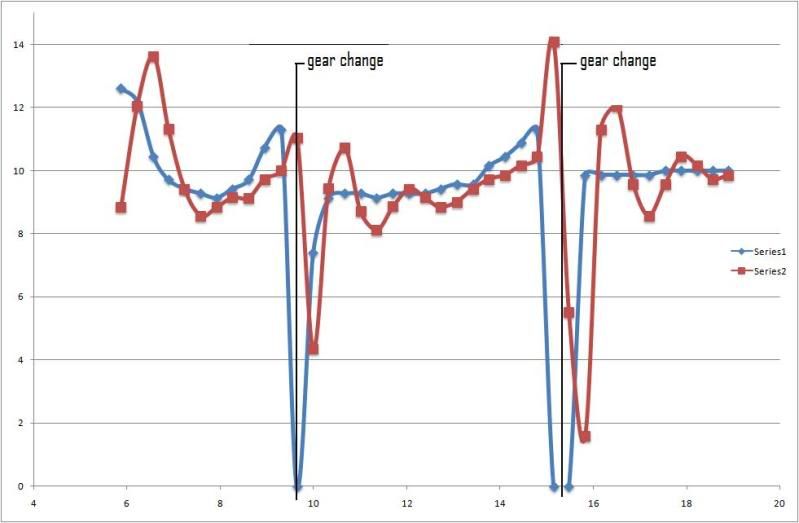

Does this look like boost demand/boost achieved?

The demand could be the blue line and the red line could represent the actual boost lagging about a second behind it. If that was the case, you can see that the engine is only demanding 9-10 psi, which is what I can see on a mechanical boost gauge. The last portion represents 4th gear and the demand(?) is bang on 10 psi.

Or maybe I'm completly wrong and its a graph for each boost control solenoid???

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users