Racing Sc Build

#1

Posted 05 October 2010 - 08:56 PM

#2

Posted 05 October 2010 - 09:08 PM

#3

Posted 05 October 2010 - 09:11 PM

#4

Posted 05 October 2010 - 09:11 PM

#5

Posted 05 October 2010 - 09:14 PM

#6

Posted 05 October 2010 - 09:17 PM

I know tvs as Thermal Vacuum StabilityTime for somebody to break out the compressor efficiency graphs again, me thinks.

I guess a lot depends on what kind of boost you want to run Doc but, I'd imagine a TVS with it's greater performance envelope is a better bet with those higher rpm's. I assume you'll go for an aftermarket ECU (or maybe the Saab ECU) to support it?

thus your statement has confused me, please qualify

yes standalone (of course)

#7

Posted 05 October 2010 - 09:20 PM

#8

Posted 05 October 2010 - 09:22 PM

#9

Posted 05 October 2010 - 09:37 PM

#10

Posted 06 October 2010 - 06:26 AM

I have a saab block with darton liners bored to 89mm

steel crank de-stroked to 78.15mm

I am thinking of building a high power core engine combined with an eaton/harrop with LS4 TB

I believe there are a fair few SC's out there

But what about a high revving units

RPM@25m/s

standard SE (94.6MM) = 7928

standard LSJ/SAAB (86MM) = 8722

special steel (78.15mm) = 9599

Would I be wise going for

1 litre eaton SC with smaller pulley

or

1.3 litre harrop SC with larger pulley

switching to the smaller crank, what are your rod / stroke ratios like now?

my build will be based on saab b204 which has much earlier stronger crank and internals with stroke 78mm and rod length 153mm. Those crazy swedes Jonas at Maptun runs these upto 10k, with 78 mm stroke and 10000 rpm it would be 5118 feet per minute or 26 meters per second.

Saab B204 78mm 153mm 1.96:1

Edited by siztenboots, 06 October 2010 - 06:26 AM.

#11

Posted 06 October 2010 - 10:06 AM

Edited by atom x, 06 October 2010 - 10:11 AM.

#12

Posted 06 October 2010 - 10:16 AM

#13

Posted 06 October 2010 - 10:18 AM

#14

Posted 06 October 2010 - 10:22 AM

#15

Posted 06 October 2010 - 10:26 AM

Thank youHARROP TVS 1320 is already better:

Looks like I could run TVS @1;1 ratio (lazy scroll)

I HAVE A CUNNING PLAN! M'LAD

#16

Posted 06 October 2010 - 10:39 AM

Centrifugal is my preferred forced induction choiceBut not sure if you want a roots blower on a pure race car engine.

Forced high rpm / high power => me think turbo or maybe centrifugal (Rotrex)

#17

Posted 06 October 2010 - 12:04 PM

rod length = 155.3

rod/bore ratio = 1.967

F1 engines do NOT exceed 25 m/s

Running greater than 25 m/s is recognised by propulsion definers as physically dangerous

They say it can't be done, then someone does it.

f1 engines are governed by sporting rules / regs , the stroke and rpm is limited.

peak piston velocity is better to know

for reference ,

2006 f1 engine, 39.77mm stroke , 98mm bore , rod2stroke 2.56:1, peak piston speed 42.4m/s, mean piston speed 26.5 m/s @20000rpm

2006 nascar cup, 82.55mm stroke , 106.3mm bore, rod2stroke 1.91:1, pps 44.6 m/s, mps 27.5 m/s @10000rpm

http://www.epi-eng.c...f_cup_to_f1.htm

Edited by siztenboots, 06 October 2010 - 12:13 PM.

#18

Posted 06 October 2010 - 12:34 PM

rod length = 155.3

rod/bore ratio = 1.967

F1 engines do NOT exceed 25 m/s

Running greater than 25 m/s is recognised by propulsion definers as physically dangerous

They say it can't be done, then someone does it.

f1 engines are governed by sporting rules / regs , the stroke and rpm is limited.

peak piston velocity is better to know

for reference ,

2006 f1 engine, 39.77mm stroke , 98mm bore , rod2stroke 2.56:1, peak piston speed 42.4m/s, mean piston speed 26.5 m/s @20000rpm

2006 nascar cup, 82.55mm stroke , 106.3mm bore, rod2stroke 1.91:1, pps 44.6 m/s, mps 27.5 m/s @10000rpm

http://www.epi-eng.c...f_cup_to_f1.htm

I did say it is not possible in theory as long as PPS is less than speed of sound, but you have quoted are old specs

from a period of high investment where one engine per race was typical

the reason for the change to the current regs is to reduce RPM to a SAFE level and reduce engine usage

I WILL NOT EXCEED 25 m/s

If you wish to exceed that good luck

Edited by atom x, 06 October 2010 - 12:41 PM.

#19

Posted 06 October 2010 - 12:43 PM

As for brit car you'll have to check the rules I was looking the other day and the first stumbling block is this little gem

20 ENGINE

20.1 The engine crank case and head, must be original units specified for that manufacture of car but maybe modified. An alternative engine from the manufacturers range may be fitted to the car but it has to be the same make of the manufacturer of the car, for example a BMW engine in a BMW M3 may only be replaced by another BMW engine. In the case of a car manufacturer that does not produce their own engines, the engine must be of a manufacturer that has been offered for sale by the car manufacturer within the period of manufacture of the chassis. The cubic capacity of an engine may be modified but the resulting volume will determine the class the car is entered into where classes are separated by engine size. If alternative engines are fitted by an entrant after the commencement of the season regulation 1.8.8 will apply. Exceptions to this regulation are limited to the following manufacturers: Marcos Mantis, TVR Tuscan and Sagaris may fit engines from the Chevrolet range; Lotus Elise and Exige may fit engines from the Honda Range. These cars must still conform to the power to weight regulations for their class.

20.1.1 The Organisers must be notified if the engine size (capacity) is altered.

20.2 Location

The engine must be installed in the original engine compartment and the crankshaft axis must be

retained in the original orientation. Intake and exhaust manifold are free.

20.3 Induction Systems

20.3.1 Forced induction is permitted provided it was part of the original specification of the respective production engine. In the case of Supercharging or Turbocharging the nominal cylinder capacity will be multiplied by 1.4 and the car will pass into the class corresponding to the fictive volume thus obtained. This means a naturally aspirated engine must remain a naturally aspirated engine; and exhaust gas turbocharger engine must remain an exhaust gas turbocharger engine; a mechanical supercharged (compressor) engine must remain a mechanical supercharged (compressor)engine

20.3.2 The replacement of a supercharger or turbocharger not complying with the original system is

eligible, for example a Garret turbocharger can be replaced by a KKK turbocharger.

20.3.3 Turbochargers or superchargers boost pressure may be changed.

So unless you can get them to accept that the LSJ is from the same manufacture then a SC engine is out.

#20

Posted 06 October 2010 - 12:47 PM

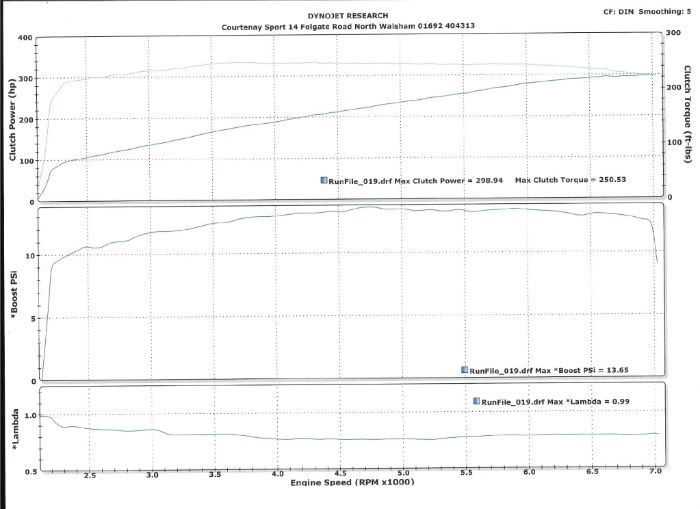

Here's my M62 with 2.9" pulley dyno chart. Shows the boost tailing off well before the kind of limits you're talking about. With the 2.9" pulley, we're already pushing the efficiency.

IMO the reason all the SC conversions tail off like that is because the laminova CC is speced for a 2 Liter engine with a 6.5k rpm. Laminovas are efficient at cooling but very restrictive.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users