Requisites:

- Crosshead screwdriver

- Small pliers (the smaller the better)

- Torx T25 screwdriver

- 10mm spanner

- 13mm spanner

- Kitchen towels

- Degreaser (WD40 seems to work okay)

- Insulating tape (waterproof)

- Toothbrush or small paintbrush for cleaning.

Optional and helpful:

- Small mirror

- Flathead screwdriver

Step 1:

Remove the little plastic cover over the motor mechanism, i've highlighted its location on the image (which i stole from this thread - sorry). It has two screws. Unplug the motor connector. Remove the windscreen washer bottle and put it aside.

Step 2:

Remove the motor assembly from the car. This is by far the hardest bit as there are four nuts to undo and they're all underneath and hard to get at. If you have a small mirror then it helps immensely, a blob of bluetack underneath it will let you rest it underneath and pointing in the right direction. If you don't have a small mirror then this is what it looks like, it'll help if you're having to do it through touch alone:

There are three nuts (10mm) holding the motor mechanism in place and a fourth one (13mm) attaching the wiper arm linkage to the spindle. I recommend you take the linkage nut off first, then you can move it out of the way. It's a splined spindle so once you've removed the nut slip a flathead screwdriver behind it to lever it off

Step 3:

Peel off the tape around the top of the motor. It should expose two slots with flat square nuts on them. Use a Torx T25 driver to undo the two bolts on the end of the motor. Be careful to make sure the two square nuts fall out of the motor and not into it. You should now be able to pull the metallic can that forms the body away from its guts. It's got two large magnets in it which will resist so give it a good tug.

Step 4:

In my case the motor was full of brown rusty water, no idea how long it'd been in there. Clean the insides. This is messy and time consuming. The reason my motor had failed was because the gunk had so thoroughly coated the commutator ring that it was rarely ever making contact with the brushes. On top of that the runners that the three carbon brushes slide back and forth in had become gunged up as well. Sliding the brushes back and forwards several times using a small pair of pliars seems to have freed them up. Degreaser would be best here, WD40 seemed to work okay for me with liberal application of kitchen towels. The components on the board aren't so important but while you're at it you may as well try to get the crap off them too. The reason my motor didn't work well was because of the amount of gunge that had accumulated on the commutator ring and brushes, electrical contact was very intermittent.

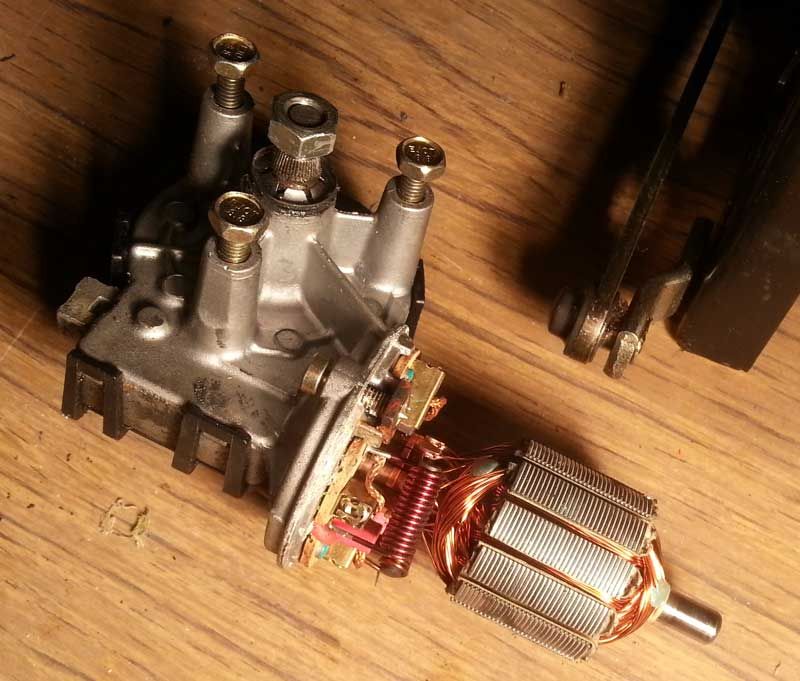

This is as clean as i could (be bothered to) get mine, and it seems to be sufficient:

Ensure there's no bits of rust from the inside of the can stuck to the armature, there's not a lot of clearance between it and the stator magnets when you put it together so a lump of rust could jam it.

Step 5:

Leave the parts somewhere warm for a bit to make sure they're dry. Put the motor back together with its two Torx bolts, the small pliars are useful here for holding the little square bolts in place as you tighten. Don't drop them inside. Note that the can is keyed, so it will only go together one way. Before you put it together make sure the ground bearing at the end of the motor spindle is clean.

Step 6:

Wrap a few turns of insulating and waterproof tape around the seal on the motor, covering the holes. There is a small hole on the back end of the can, it might be worth covering that as well in case that's how the water gets in there in the first place.

Step 7:

Put it back in the car. Do everything in reverse and you should be okay. Don't attach the link arm yet, just do up the three mounting bolts. Re-attach the 5wire connector and turn the car on, and set the wipers to intermittant. You will be able to hear the motor going, when it stops to pause turn the car off again. This ensures that the motor is in the "bottom left" position. Manually move the wiper blade so that it's in the rest position and then attach the linkage arm. Make sure you do the bolt up tightly, if it's loose it will strip the splines over time and then you really will need a new motor.

Step 8:

If you used a mirror then don't forget to take it out or your girlfriend will kill you for losing her makeup mirror. Put the little plastic cover back on and put the windscreen washer bottle back in place.

Hope that helps someone else some day!