TIS doesn't give a torque setting for the studs, i suppose they'll torque up with the torque of the bolt, but it would be better to have a torque for both.

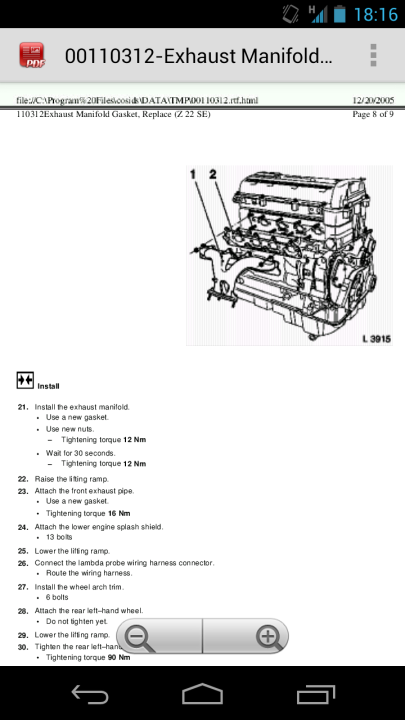

12Nm according to this

http://www.speedster...nes (Z22SE).pdf

That that doesn't sound anywhere near enough to me... (Page11)

Edited by Chris P Duck, 25 March 2013 - 05:34 PM.