The 65mm throttle (for the few who may still be unaware) is not a straight bolt-on to the z22se inlet manifold.

Plenty has been written about the benefits and drawbacks of using a 65mm, and there are adapter plate photos from other members (from who's work I will crib when I get to that point.)

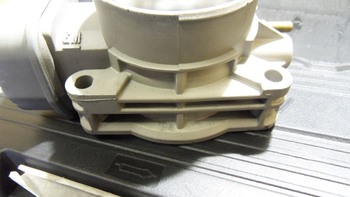

The 65mm throttle body weight is 0.986kg.

As a comparison the standard 58mm TB is 0.904kg. Please ignore the dissasembled nature of this TB - it's for a small idea I had.

Everyone likes a throttle butterfly modification - worth at least 1/10th of a horsepower - and the standard plate weighs in at a porky 0.061kg.

I grit blasted it and then profiled the leading and trailing egdes - sharp (but not razor sharp as you won't get a seal on the venturi) on the leading edge and more slowly tapered on the trailing edge. The throttle shaft wake makes a sharp taper redundant and i'd rather not risk the plate not closing well.

That shaved 0.004kg from the plate to get it down to 0.057kg. Thats a 7% saving.

There is a serious point about reducing any rotating mass - the TB motor and return spring have to do work (opening and closing repectively) so less mass is less momentum and should open and close more quickly. I am perfectly happy to admit it will be as good as non-detectable, but I get satisfaction knowing it's (not) there.

Some general post-blasting shots (tape up the venturi, fuel vapour inlet and the electrical connector if you are going to blast).

Assembled and some material removed from non-essential areas as well as a reduction in areas of the butterfly shaft.

Final weight (the butterfly screws are on the scale) is 0.967kg, so still 0.063kg adrift of the 58mm I'm confident there is another 10g to be had, but the real mass is in the motor and throttle shaft.

Next jobs are to do the adapter plate, the wiring harness extension and the ECU code.