Fitting Webcon Throttle Bodies

#41

Posted 25 November 2012 - 04:51 PM

#42

Posted 25 November 2012 - 05:10 PM

#43

Posted 25 November 2012 - 06:25 PM

As a matter of interest, has anyone supercharged AND installed webcon? I know that mating/making a plenum to feed into the 4 barrels might be tricky, but the result would be good surely ?

Not sure there'd be room to squeeze it all in

#44

Posted 25 November 2012 - 06:28 PM

#45

Posted 25 November 2012 - 06:31 PM

As a matter of interest, has anyone supercharged AND installed webcon? I know that mating/making a plenum to feed into the 4 barrels might be tricky, but the result would be good surely ?

Not sure there'd be room to squeeze it all in

Well, if my future plans don't make enough of a difference maybe I'll give it a go

There's certainly a lot of empty space in the engine bay. I guess it's just a case of whether there's room between the ITBs and the bulkhead to fit any of the necessary gubbins in there.

#46

Posted 25 November 2012 - 08:00 PM

Edited by vocky, 25 November 2012 - 08:03 PM.

#47

Posted 25 November 2012 - 08:25 PM

#48

Posted 25 November 2012 - 08:32 PM

#49

Posted 25 November 2012 - 08:35 PM

it does make access so much easierNow thats the mother of all inspection hatches!!!

that is my old engine, which ran the Saab oil cooler (just to the right of the oil filter). My new engine will be using the vx220 oil coolerNot running the oil cooler?

#50

Posted 25 November 2012 - 08:38 PM

it does make access so much easier

Now thats the mother of all inspection hatches!!!

Didn't make mine quite so big but with hindsight would have done!

Already saved me form a certain engine out job to fix an oil leak that would have been nigh on impossible without the access it gave

#51

Posted 25 November 2012 - 08:47 PM

#52

Posted 25 November 2012 - 08:52 PM

#53

Posted 26 November 2012 - 01:00 PM

4mm alloy panel to cover it

4mm? It doesn't need to be bullet proof !

#54

Posted 26 November 2012 - 02:36 PM

Not yet, the Rotrex would workAs a matter of interest, has anyone supercharged AND installed webcon? I know that mating/making a plenum to feed into the 4 barrels might be tricky, but the result would be good surely ?

Its a fire wall

4mm alloy panel to cover it

4mm? It doesn't need to be bullet proof !

#55

Posted 27 November 2012 - 02:04 PM

#56

Posted 27 November 2012 - 02:14 PM

#57

Posted 27 November 2012 - 02:30 PM

#58

Posted 27 November 2012 - 05:51 PM

#59

Posted 28 November 2012 - 03:15 PM

#60

Posted 28 November 2012 - 03:36 PM

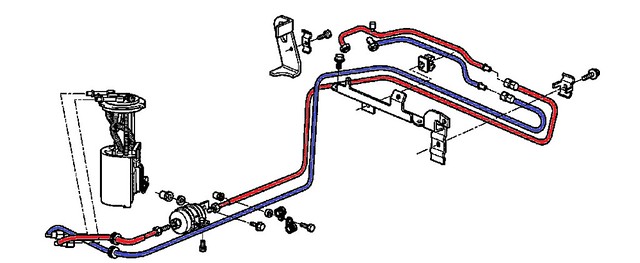

You also have to modify a relay in the boot (which is tucked right up over the nsr wheel arch) as follows: cut the thin brown wire (where it joins the big brown wire) on the brown relay base and join it to the white/violet wire on the grey relay base (so both relays get power from the white/violet)

The z22se ecu switches the negative on the brown relay, it has a permanent live feed, webcon added a negative but there are no switched negatives coming from the webcon ecu.

Edited by vocky, 28 November 2012 - 03:38 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users