I've Sat In Enough Traffic Jams Before...

#21

Posted 05 May 2008 - 11:39 AM

#22

Posted 05 May 2008 - 05:45 PM

#23

Posted 05 May 2008 - 05:46 PM

when i took my group buy (this forum) 10.9 bolts to Plans to fit when i was having the nitrons done they refused to fit them, graham got quite animated about it - they fitted the 8.8's instead. Peeved me cos the long ones are fekkin expensive.

edit/ didn't see any body damage which was lucky

What reason did he give?

#24

Posted 05 May 2008 - 05:52 PM

when i took my group buy (this forum) 10.9 bolts to Plans to fit when i was having the nitrons done they refused to fit them, graham got quite animated about it - they fitted the 8.8's instead. Peeved me cos the long ones are fekkin expensive.

edit/ didn't see any body damage which was lucky

What reason did he give?

#25

Posted 05 May 2008 - 07:20 PM

#26

Posted 05 May 2008 - 07:32 PM

The reason they gave simply that they would prefer them to bend rather than snap. I think it was Graham that had the concerns rather than John because i discussed fitting the GB bolts with him and he was ok about it. In fact he even emailed me to say that i should check that they were 10.9 and not 12.6.

Hmm - seems like they've changed their mind.....

I called them to ask about this a while ago and they said that the 12.6 ones were too brittle, and the 10.9 ones are OK.

However, they did just say that you're better off just fitting standard ones and replacing them regularly.

#27

Posted 05 May 2008 - 07:36 PM

My car had the bolts fitted by plans in March this yearThe reason they gave simply that they would prefer them to bend rather than snap. I think it was Graham that had the concerns rather than John because i discussed fitting the GB bolts with him and he was ok about it. In fact he even emailed me to say that i should check that they were 10.9 and not 12.6.

Hmm - seems like they've changed their mind.....

I called them to ask about this a while ago and they said that the 12.6 ones were too brittle, and the 10.9 ones are OK.

However, they did just say that you're better off just fitting standard ones and replacing them regularly.

#28

Posted 05 May 2008 - 07:51 PM

#29

Posted 05 May 2008 - 07:58 PM

are the bolts hard to change?

In theory no, in practice they can have you swearing at them. You'll need a socket set and the right combination of bits to gain access. Then hope they're not in too tight to undo or that the heads have rounded.

As for Plans, Lotus recommend the 10.9 bolts so that's good enough for me.

#30

Posted 05 May 2008 - 08:20 PM

Think it is time for Vauxhall to fess up and accept the fact they need a recall on this. maybe worth sending these photo's to VOSA

I don't think so somehow.

Any modification whether it be a remap or suspension upgrade = warranty void. Vauxhall would laugh at this unless it happened to a standard set-up and to a good few.

As for VOSA, all they are interested in is Government legislations re. MOT rules/criteria.

This aside, thank goodness the out come was that nobody was hurt

Edited by Penny, 05 May 2008 - 08:25 PM.

#31

Posted 05 May 2008 - 08:37 PM

The bolts that were eventually fitted to my car were the lotus ones and were 8.8 grade. There seems to be a bit of confusion here. i'll give Plans a call if i have time tomorrow.are the bolts hard to change?

In theory no, in practice they can have you swearing at them. You'll need a socket set and the right combination of bits to gain access. Then hope they're not in too tight to undo or that the heads have rounded.

As for Plans, Lotus recommend the 10.9 bolts so that's good enough for me.

#32

Posted 05 May 2008 - 08:39 PM

#33

Posted 05 May 2008 - 09:18 PM

12.x bolts are far far far too brittle and will snap faster than the 8.8's

there is a lotus upgrade part of 10.9 bolts.

I'd guess plans were covering their arses with only fitting 8.8's incase something went wrong with the 10.9's

Mmmmm... the 12.x I got from ebay are deffo going in the bin then...

Edited by ukgulf, 05 May 2008 - 09:18 PM.

#34

Posted 05 May 2008 - 09:24 PM

#35

Posted 05 May 2008 - 10:24 PM

#36

Posted 06 May 2008 - 07:54 AM

I think i will get them changed for peace of mind every other service. This might be overkill but it doesn't bear thinking about if this were to occur at speed. Now whether fitting the 8.8's will give you any warning that the HCB's are knackered before they break I don't know. I remember a photo on this site showing a bolt that had been removed which was bent and chewed which is a lot better than a broken one, i wonder what grade of s/s it was?

#37

Posted 06 May 2008 - 08:30 AM

OK i have been on to Graham at Plans. He told me that as far as he knows there has not been a revised specification by Lotus to these bolts. Furthermore, he has worked on new Lotuses and they all have the 8.8 bolts on. His comment was if you go against the spec and there is a problem then who do you sue. He, as a motorsport tuning company does not want to have any blame laid at his feet which is understandable.

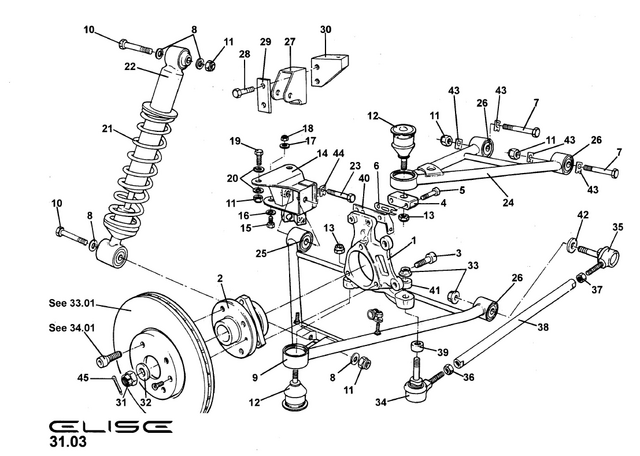

Lotus only revised the rear hub carrier bolts to be 10.9, the fronts are still 8.8 (see below).

However there have been occassions of the front ones failing, although it's less likely due to the lower forces and the fact that people remove more of the camber shims making the torque transfered to the clamp load more effective.

Information from the 111 S2 using steel uprights

The original A111W7145F M10x50 bolt rear hub carrier is grade 8.8 and the service manual states torque 45Nm or 33lbft (NOTE some S2 parts manuals list Rear suspension part #5 as A111W1745F which is probably a misprint)

In 2004 Lotus issued service bulletin 2004/08 which revised the part number to A117W7212F with a new 10.9 grade specification to be torqued to 68Nm or 50lbft for motorsport use.

The front bolts A111W7155F and A1117W144F are not affected and remain 8.8 grade and 33lbft torque.

#38

Posted 06 May 2008 - 09:00 AM

Edited by simsy, 06 May 2008 - 09:08 AM.

#39

Posted 06 May 2008 - 01:01 PM

#40

Posted 06 May 2008 - 01:20 PM

Which bolt is best is open (Lotus factory recommendations will be the most balanced), but any bolt that is tight and in good condition will not fail unless you hit a kurb or bump very hard and do not replace them.... (This last bit is just my opinion)

Not strictly true, it is only if the clamp force in the Joint, caused by torquing the bolt, is greater than the load on the joint.

The clamp force for a given torque can vary quite a lot due to different factors the 2 main ones in the hub bolts are the friction on the threads and the number of interfaces introduced by the camber shims, as they cause a loss of clamp force due to embedding.

Edited by Winstar, 06 May 2008 - 01:21 PM.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users