Toe Link Options....

#21

Posted 05 February 2010 - 04:07 PM

#22

Posted 05 February 2010 - 04:10 PM

How about this, putting a strong plate of metal through the 2 bolts which hold the rear diffuser on?

#23

Posted 05 February 2010 - 04:10 PM

#24

Posted 05 February 2010 - 04:12 PM

is there any reason you cant just get a strip of metal and bolt it on the subframe therefore making your own brace bar for like.... say.... £5

whats stopping people from doing this?

I've wondered about one that is plates that bolts to the sub frame around the toe link then a bar between them more like a strut brace.

#25

Posted 05 February 2010 - 04:14 PM

im on about just bolted into higher, so it doesnt touch the toe link

or wouldthat also need to be spring bearing?!

the nut that hold the big bolt for the diffuser is only tack welded to the frame.

better weld bracket to the lower wishbone and connect toe link to that

Edited by siztenboots, 05 February 2010 - 04:16 PM.

#26

Posted 05 February 2010 - 04:42 PM

No doubt Gaz will pop up to talk about the brace bar soon but one of the prime advantages of it is that it is incredibly strong in that plane, you are able to put it under preload and it is also very lightweight, the whole kit I think weighs about 700g.

Is the kit substantial enough....? I've heard stories of links wearing out on them after prolonged track use (which I'm going to give it).

#27

Posted 05 February 2010 - 04:46 PM

is there any reason you cant just get a strip of metal and bolt it on the subframe therefore making your own brace bar for like.... say.... £5

whats stopping people from doing this?

I've wondered about one that is plates that bolts to the sub frame around the toe link then a bar between them more like a strut brace.

I can't see why this would not work as it is the two towers that flex. By joining them together will this not significantly reduce flex? The only downside may be that more stress may be put in the tie rod and tie rod mounting point.

If you look at the spitfire design the brace bar is attached to the sub-frame via brackets it is not connected directly to the tie rods like some designs (I know the tie rod and brace bar brackets are bolted together). Could the spitfire brace bar not be used on its own with some revised brackets?

Cheers Oakmere

#28

Posted 05 February 2010 - 06:06 PM

#29

Posted 05 February 2010 - 06:50 PM

#30

Posted 05 February 2010 - 07:16 PM

is there any reason you cant just get a strip of metal and bolt it on the subframe therefore making your own brace bar for like.... say.... £5

whats stopping people from doing this?

I've wondered about one that is plates that bolts to the sub frame around the toe link then a bar between them more like a strut brace.

exact what i am doing i have got hold of some secound hand spitfire tie rods i am going to fit them and then bolt a brace bar between them .brace bar being steel box section powder coated to stop rusting Job Done

Edited by leevx2.2, 05 February 2010 - 07:18 PM.

#31

Posted 05 February 2010 - 07:18 PM

exact what i am doing i have got hold of some secound hand spitfire tie rods i am going to fit them and then bolt a brace bar between them .brace bar being steel box section Job Done

make sure lee the joint have been updated

#32

Posted 05 February 2010 - 07:20 PM

exact what i am doing i have got hold of some secound hand spitfire tie rods i am going to fit them and then bolt a brace bar between them .brace bar being steel box section Job Done

make sure lee the joint have been updatedthe batch i bought was the new batch

I have got to replace 2 joints on them so they are the old but soon to be the new FAb

#33

Posted 05 February 2010 - 07:34 PM

I have got to replace 2 joints on them so they are the old but soon to be the new FAb

good man...sorry i wouldn't like to come with my dustpan and brush to collect the peaces

always think on the safety of members

paypall is good

#34

Posted 05 February 2010 - 08:37 PM

#35

Posted 05 February 2010 - 09:31 PM

My plan is to get new inner joints from EP for £35 each. Gives me the peace of mind, and I am not running track tyres.

The kits with brace bars just cost too much for me.

my point was I don't understand why the brace bar has to have expensive spherical bearings on it, if it is designed to be bolted to the subfame at either end then all it should need is a bar with opposing thread so it can be tensioned.

I'm thinking of going back to the std toe links as i'm just not getting enough track time and am really not a fan of sticky tyres.

#36

Posted 05 February 2010 - 09:39 PM

My plan is to get new inner joints from EP for £35 each. Gives me the peace of mind, and I am not running track tyres.

The kits with brace bars just cost too much for me.

my point was I don't understand why the brace bar has to have expensive spherical bearings on it, if it is designed to be bolted to the subfame at either end then all it should need is a bar with opposing thread so it can be tensioned.

I'm thinking of going back to the std toe links as i'm just not getting enough track time and am really not a fan of sticky tyres.

What are you running on now Rob...? Perhaps a deal could be afoot

#37

Posted 06 February 2010 - 08:49 AM

My plan is to get new inner joints from EP for £35 each. Gives me the peace of mind, and I am not running track tyres.

The kits with brace bars just cost too much for me.

my point was I don't understand why the brace bar has to have expensive spherical bearings on it, if it is designed to be bolted to the subfame at either end then all it should need is a bar with opposing thread so it can be tensioned.

I'm thinking of going back to the std toe links as i'm just not getting enough track time and am really not a fan of sticky tyres.

What are you running on now Rob...? Perhaps a deal could be afoot

I'm on the spitfire without brace bar, although the outer collet will probably be the wrong size for a turbo.

#38

Posted 06 February 2010 - 09:07 AM

my point was I don't understand why the brace bar has to have expensive spherical bearings on it, if it is designed to be bolted to the subfame at either end then all it should need is a bar with opposing thread so it can be tensioned.

exactly Mr Winstar! surely this is all that is needed! just bolt it to the subframe, not through the toe links.

you cant really see but this one is adjustable in the middle

surely you just need one like this which has 1 bolt either end and an adjuster in the middle?!

#39

Posted 11 February 2010 - 08:10 AM

#40

Posted 11 February 2010 - 10:31 AM

<!--quoteo(post=993783:date=Feb 5 2010, 15:18 :name=joe_589)--><div class='quotetop'>QUOTE (joe_589 @ Feb 5 2010, 15:18 ) <a href="index.php?act=findpost&pid=993783"><{POST_SNAPBACK}></a></div><div class='quotemain'><!--quotec-->is there any reason you cant just get a strip of metal and bolt it on the subframe therefore making your own brace bar for like.... say.... £5 <img src="http://www.vx220.org...IR#>/laugh.gif" style="vertical-align:middle" emoid="

" border="0" alt="laugh.gif" />

whats stopping people from doing this?<!--QuoteEnd--></div><!--QuoteEEnd-->

I've wondered about one that is plates that bolts to the sub frame around the toe link then a bar between them more like a strut brace.

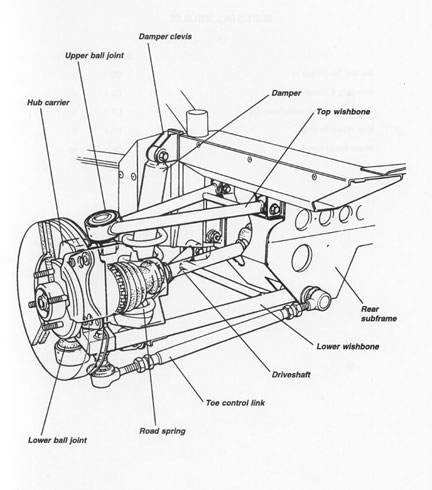

The reason to move away from a solid mount is because the arms of the subframe flex in two dimensions and as a consequence can move in the third relative to each other.

The arms can move up and down or closers etc. when they both move in the same direction then they will form a parallel shape where the 90 degree point at each end no longer match.

As Lotus found out when they used a fixed bush to locate the brace on the 111S they wear out very quickly (take a look at the US forums, some lasted one track-day!)

A bearing ended brace will restrict movement in the plane you wish to control but allows the others to move freely.

If you have a solid mount on your subframe then the joint is still under under continuos load, this in time may have either of two results either the area around the subrame where the mount is will fatigue or the brace will.

If you wanted to go that route then a custom welded bracket is probably better.

Anyway you should have some flex in the system as it was designed in as part of the structural fatigue resistance. if you remove this movement without a thorough stress anylsis you may induce stress cracks all over the place and not necessarily where you expect.

Lotus moved the 111S brace back to rod-ends, and I bet they spent more money on prior analysis before doing this that you or I are prepared to spend on beer

Edited by Spitfire Engineering, 11 February 2010 - 10:37 AM.

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users