First of all, what is it? It is a piece of phenolic resin plastic in the shape of an inlet manifold gasket that sits between the cylinder head and the inlet manifold. The aim is to reduce heat soak from the head into the inlet manifold by insulating it. Anything you can do to reduce the charge temperature is a good thing in terms of reducing detonation and increasing power. In all, the spacer, along with two gaskets, comes to about 10mm thick which introduces some problems...

1) The lower manifold support bracket.

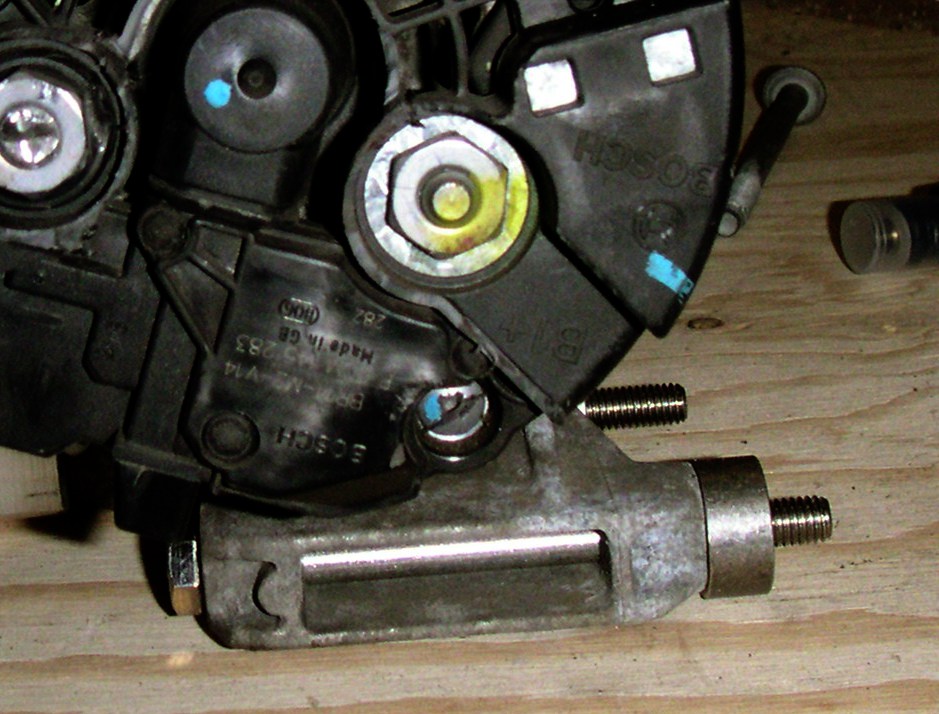

The threaded hole at the bottom of the inlet manifold where the support bracket attaches is 10mm further away from the block. In my case, I could get the proper GM bracket from neither Courtenay's or anywhere in the USA. (Personally, I suspect the supply has dried up entirely). I was really not at all happy about the idea of running it without so I made one.

Actually, I think not being able to get a GM one did me a favour as it forced me to make one that matched the spaced out position of the inlet manifold where as a stock bracket would have to be spaced out. I was very careful to make sure it fitted perfectly by dry assembling everything but did take the precaution of slotting out the manifold mounting bolt hole slightly fore-aft to allow for the extra thickness of the pair of gaskets. If you get it wrong up-down then it will force open a gap between the manifold to head. When doing the final assembly, the bolt going into the manifold side was put in after the head bolts, before the weight of the supercharger was added and did not force the manifold in any direction. When the bolt is tightened, it braces the whole thing.

2) Alternator spacers

With a ‘normal’ install, the 100A alternator with the plastic cut out already barely fits. Once the manifold is spaced out, the positive terminal well and truly fouls the manifold so the only option is to space out the alternator by the same 10mm. I machined up 4 spacers to sit between the alternator and the block. It also requires longer bolts!

3) Spacer and gasket alignment

The Z22SE fitted to the VX uses 6mm bolts and studs to hold the manifold on. I can only assume that the American Cobalts and Saturns use 8mm bolts as the Supercharger inlet manifold has 8mm holes! Without some intervention, it would mean that the spacer and gaskets would be free to float about all over the place whilst you try and bolt up the manifold and prove impossible to align them to the ports. Courtenay’s do sell a very expensive “Inlet Manifold Alignment Bung” but that wouldn’t necessarily work with the spacer.

I got hold of some 8mm OD/6mm ID alluminium tube and made up alignment tubes. The trick here is to get the length just right - too short and it would allow one of the gaskets to escape alignment - too long and the bolts will bottom out on the tube and not secure the manifold. I dare say that you could get away with fitting a couple and it would do the job but I ended up making them for all 7 bolts/studs. Make sure you apply copperslip to the bolt shafts to prevent the tubes binding over time.

4) Belt

The final ‘gotchya’ is that the belt you buy from Courtney’s will now be too short so be prepared! I found that a 1288 belt was perfect for mine but am running a slightly smaller than standard pulley.

I hope that was of some use!