At least its the cold end thats closest to the CV boot. Great work BTW ![]()

2.2 Turbo

#21

Posted 20 February 2015 - 12:53 PM

#22

Posted 20 February 2015 - 03:56 PM

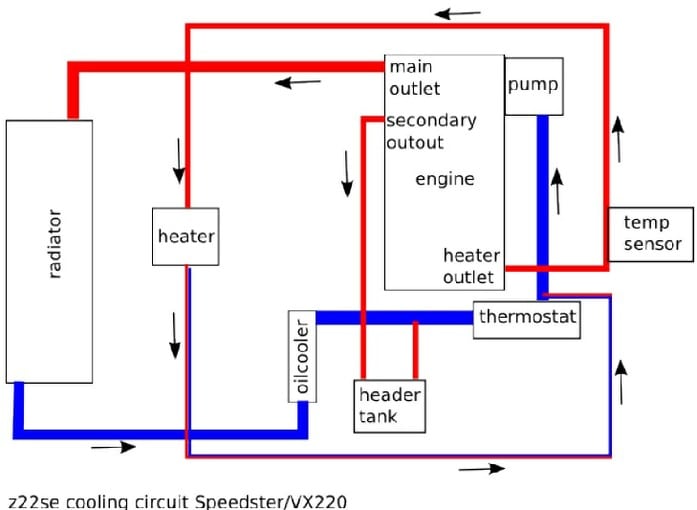

Ok, some coolant questions:

[color=rgb(20,20,20);font-family:'PT Sans', sans-serif;background-color:rgb(252,252,255);]Here's the schedule from MarkV on the VX coolant flow:[/color] [color=rgb(20,20,20);font-family:'PT Sans', sans-serif;background-color:rgb(252,252,255);] [/color]

[color=rgb(20,20,20);font-family:'PT Sans', sans-serif;background-color:rgb(252,252,255);] [/color]

I'm going to get the coolant feed from the waterpump (from drain bolt).

[color=rgb(20,20,20);font-family:'PT Sans', sans-serif;background-color:rgb(252,252,255);]A) If I am correct, the z20net has a return in the "main outlet"? Correct?[/color]

[color=rgb(20,20,20);font-family:'PT Sans', sans-serif;background-color:rgb(252,252,255);] ![]() The US Cobalt guys say to put the return into the "secondary outlet", straight back to the reservoir. I think this would not be such a great idea since you are warming up the cold water that is suppose to cool the engine (warm out and warm in....). Correct?[/color]

The US Cobalt guys say to put the return into the "secondary outlet", straight back to the reservoir. I think this would not be such a great idea since you are warming up the cold water that is suppose to cool the engine (warm out and warm in....). Correct?[/color]

[color=rgb(20,20,20);font-family:'PT Sans', sans-serif;background-color:rgb(252,252,255);]C) Tapping into the thermostat means you recirculate the hot water into a cold circuit and putting hot water into the engine. Not that good. Correct?[/color]

[color=rgb(20,20,20);font-family:'PT Sans', sans-serif;background-color:rgb(252,252,255);]I would go with option A. Any comments on this one? Thanx![/color]

[color=rgb(20,20,20);font-family:'PT Sans', sans-serif;background-color:rgb(252,252,255);]For about the close turbo/driveshaft issue: The DBilas kit is even closer (with the hotside of the turbo in the driveshaftboot direction!) and holds up so far. Except for some melted gearcables here and there ....[/color]

#23

Posted 22 February 2015 - 09:35 PM

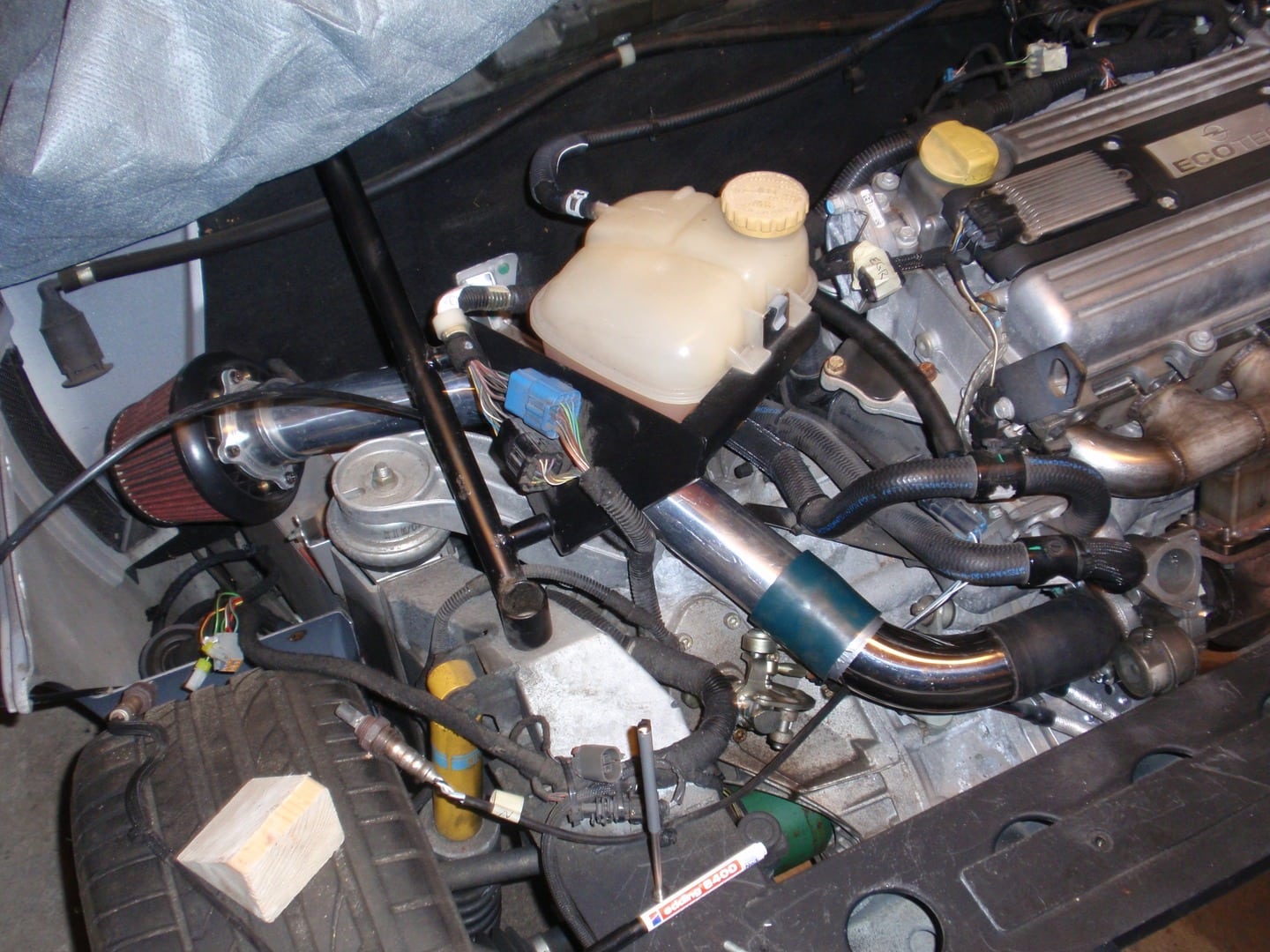

Ok, so bought this :

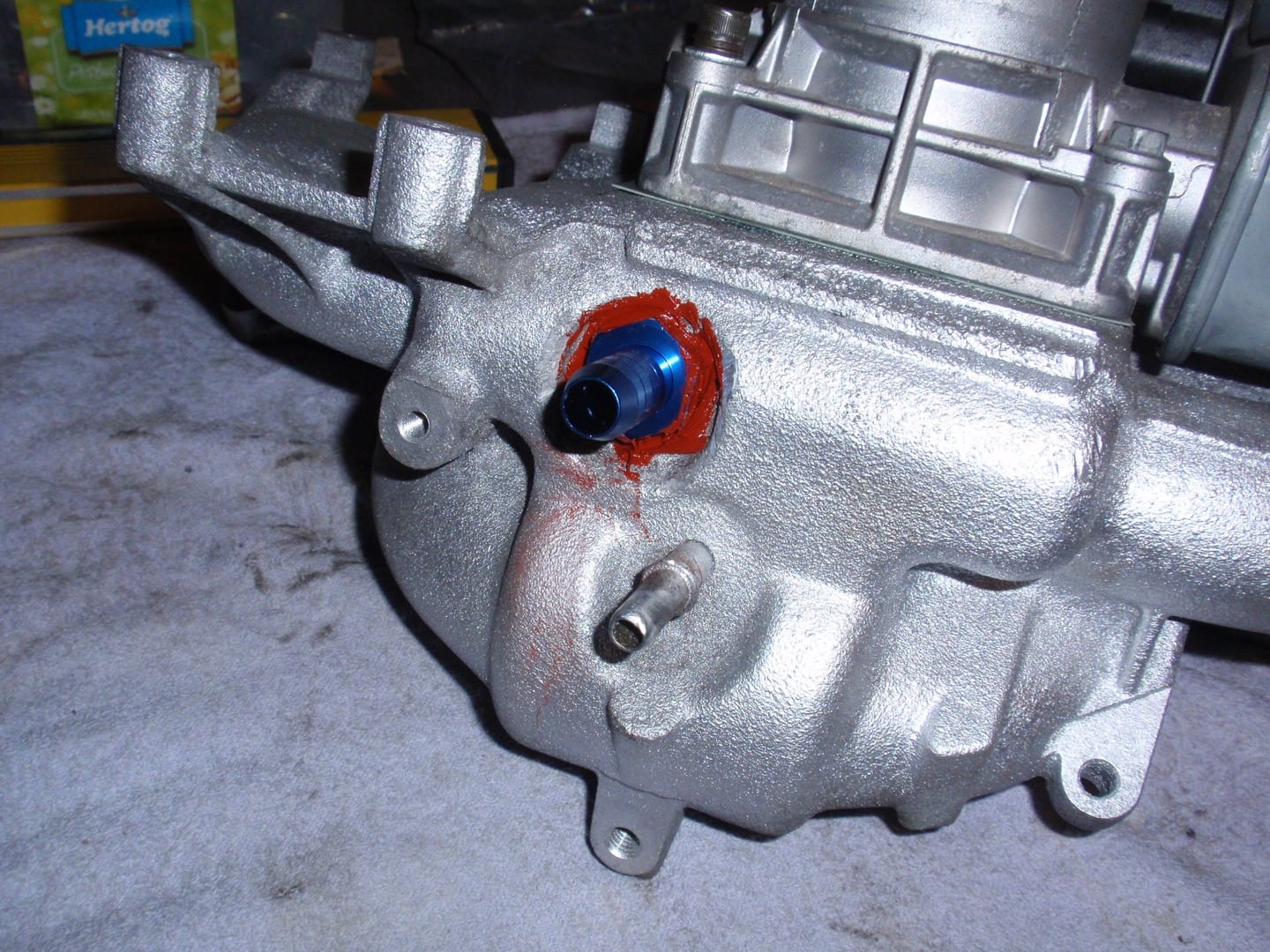

Put my waterreturn into the "main outlet".

Modified the OEM heatshield and looks and fits fine so far:

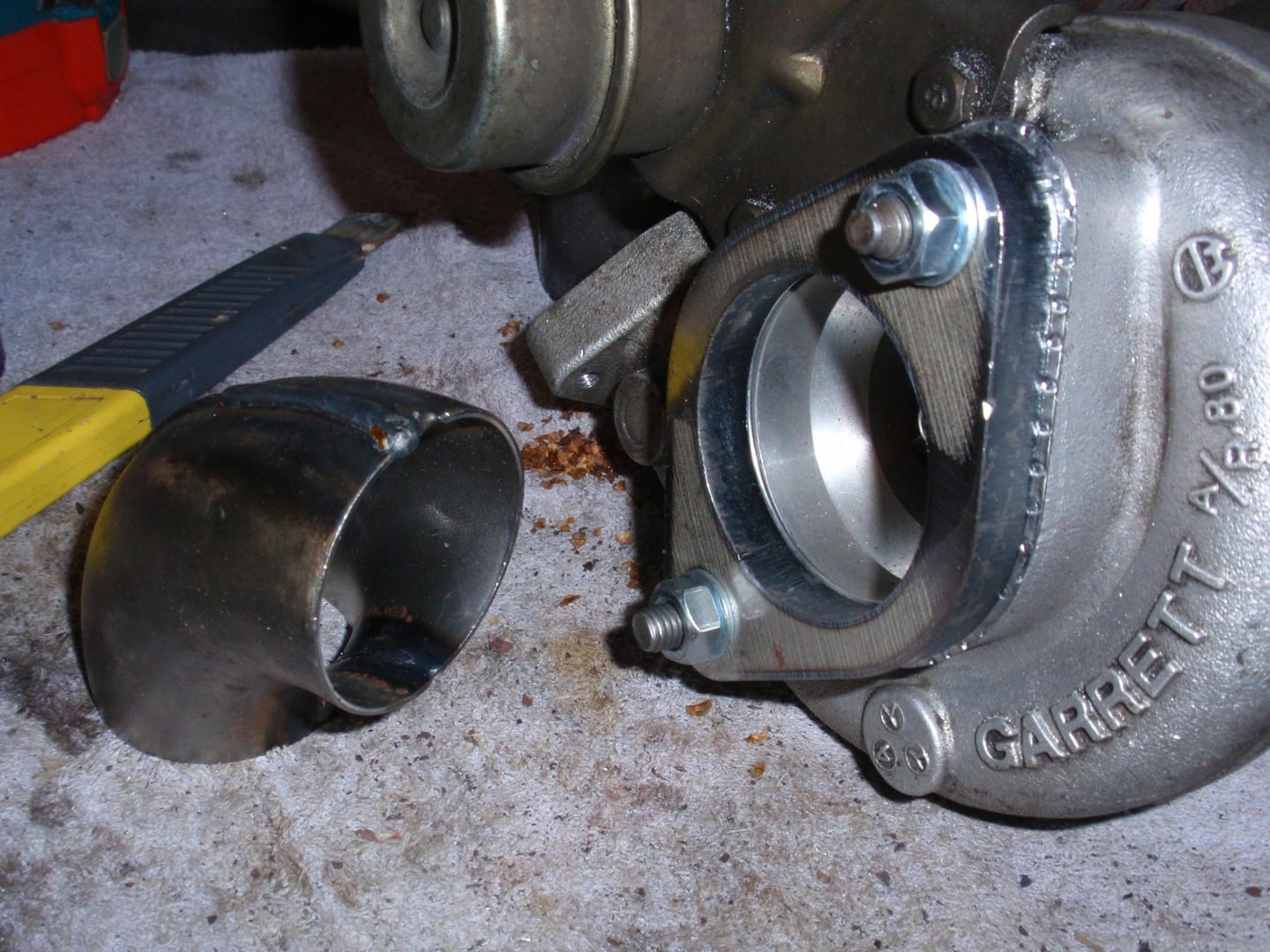

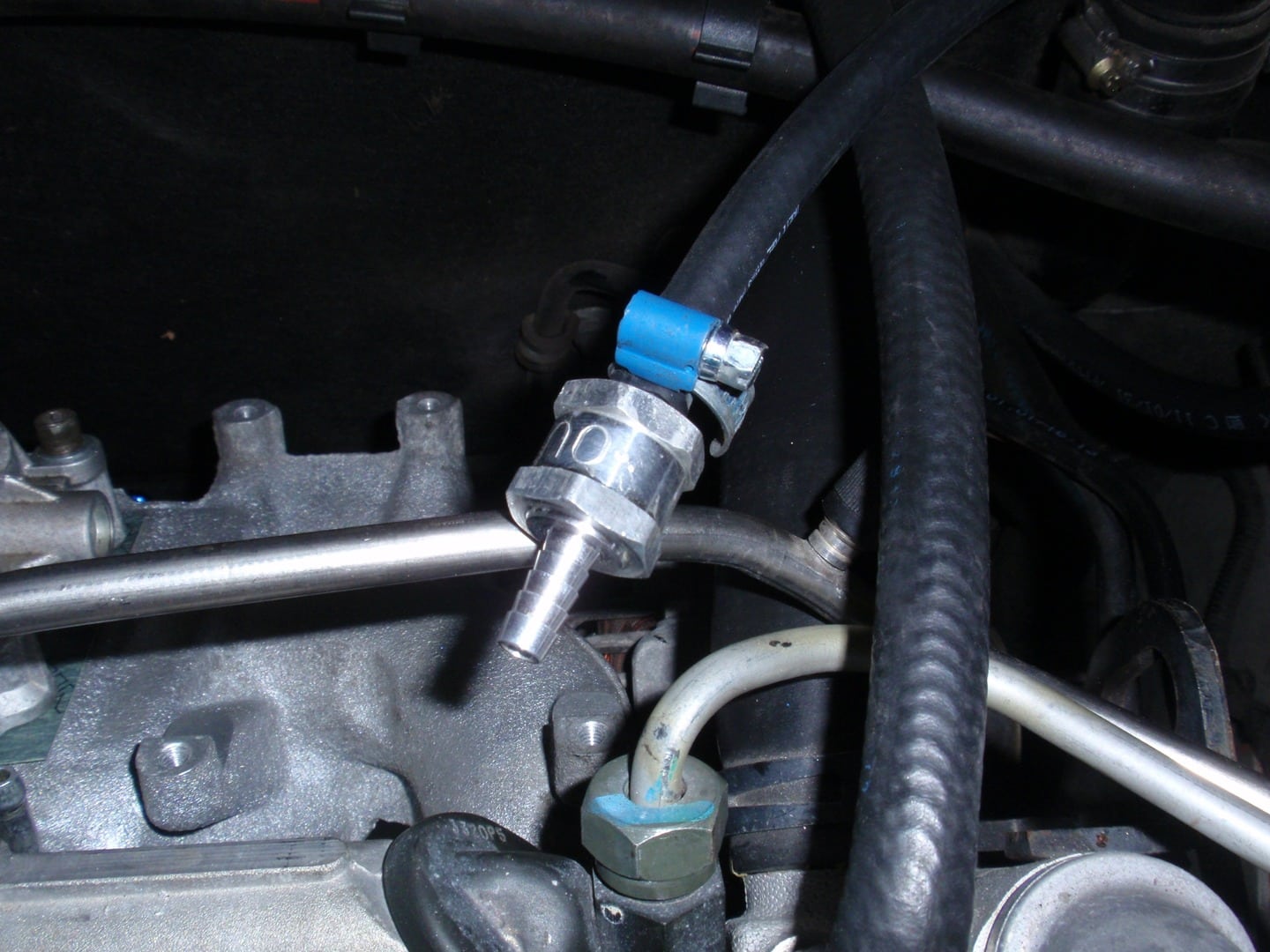

Drilled my banjo bolt to 1.5mm as a oilrestrictor for the non ballbearing turbo:

Got myself a 2.5" Imhof backbox so now I can sort out the rest of the exhaust.

#24

Posted 10 March 2015 - 09:50 PM

#25

Posted 12 March 2015 - 01:27 PM

looking intersting

#26

Posted 13 March 2015 - 10:45 PM

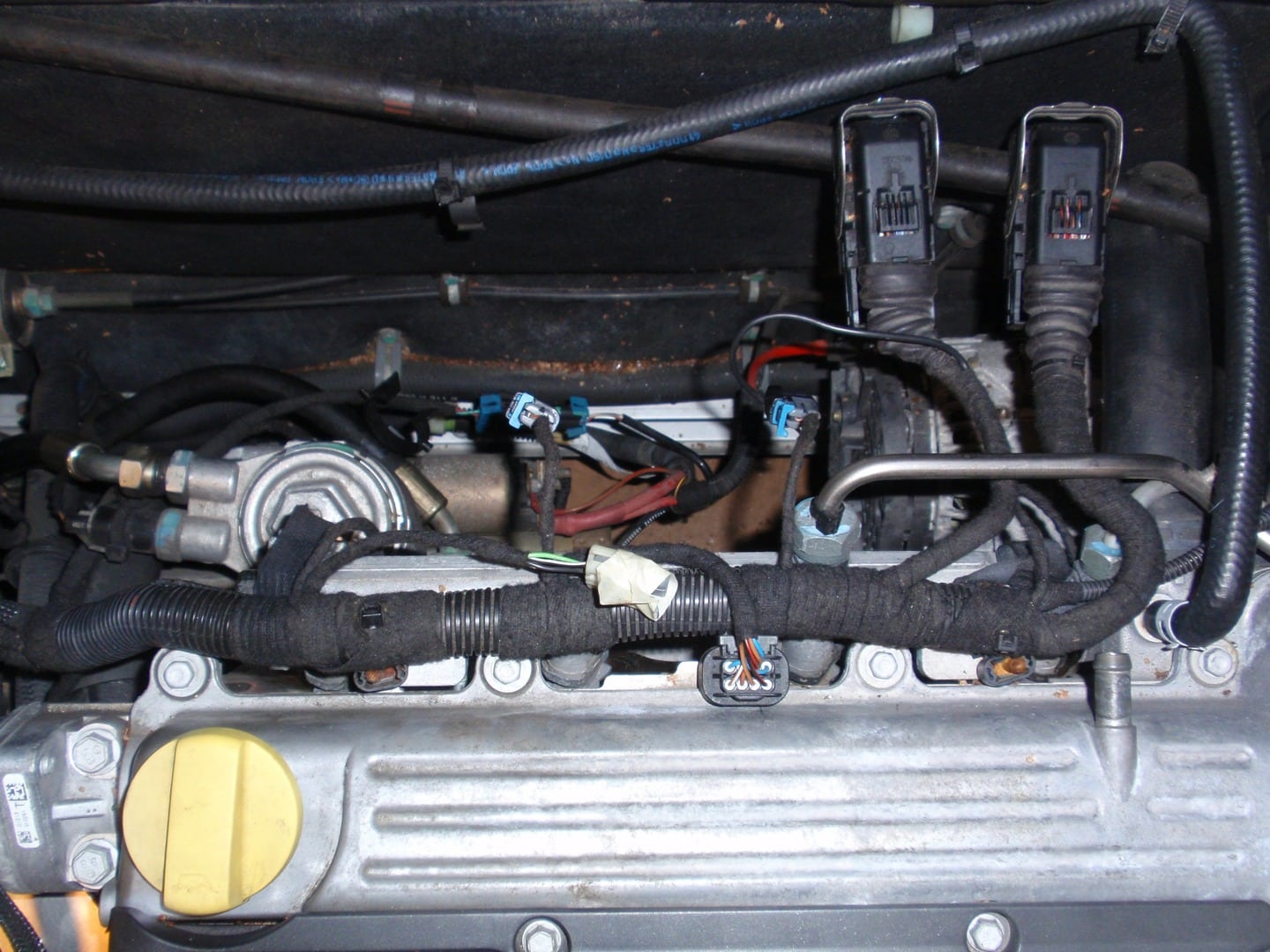

Got a saab intake today from Exmantaa.... thanx mate ![]()

TB-hole is 60mm

TB and ECU fit perfect 1-on-1

Manifold shuts the OEM pcv hole (from cilinderhead 2 -3) perfect shut.

Shut the manifold pcv to prevent unmetered air coming in in vacuum situation

Perfect fit with 120A alternator

#27

Posted 14 March 2015 - 10:11 AM

#28

Posted 31 March 2015 - 08:34 PM

#29

Posted 31 March 2015 - 11:08 PM

How much boost will you use ?

#30

Posted 01 April 2015 - 07:35 AM

Max. 0.8 bar / 12 psi.

#31

Posted 01 April 2015 - 07:52 AM

I'm really hoping this works well :![]() :

:

#32

Posted 01 April 2015 - 07:58 AM

Just a thought after looking back through your pics.....

You may want to slot the exhaust flange in between the cylinders or elongate the holes for the exhaust studs. Stainless expands quite a lot and log manifolds like this can end up snapping studs off if they don't have a bit of wiggle room.

#33

Posted 01 April 2015 - 09:19 AM

Yes I know, thank you. Most of them are m10 size with a M8 stud but a few were very tight so I opened them later on to M10 size hole. Should be sufficient I guess?

#34

Posted 01 April 2015 - 11:42 AM

Should be fine. ![]()

Can't wait for the result ![]()

#35

Posted 24 April 2015 - 09:56 PM

[color=rgb(20,20,20);font-family:'PT Sans', Arial, sans-serif;background-color:rgb(252,252,255);]Short updat so far:[/color]

[color=rgb(20,20,20);font-family:'PT Sans', Arial, sans-serif;background-color:rgb(252,252,255);]TMAP 2.5 bar placed. Used the OEM MAP hole but the gap is alrger then the rubbe r0-ring. So a little ghetto helper to keep the sensor down.[/color] [color=rgb(20,20,20);font-family:'PT Sans', Arial, sans-serif;background-color:rgb(252,252,255);] [/color]

[color=rgb(20,20,20);font-family:'PT Sans', Arial, sans-serif;background-color:rgb(252,252,255);] [/color]

[color=rgb(20,20,20);font-family:'PT Sans', Arial, sans-serif;background-color:rgb(252,252,255);]Blocked the crackhole to prevent dirty oil vapors getting into the manifold.[/color]

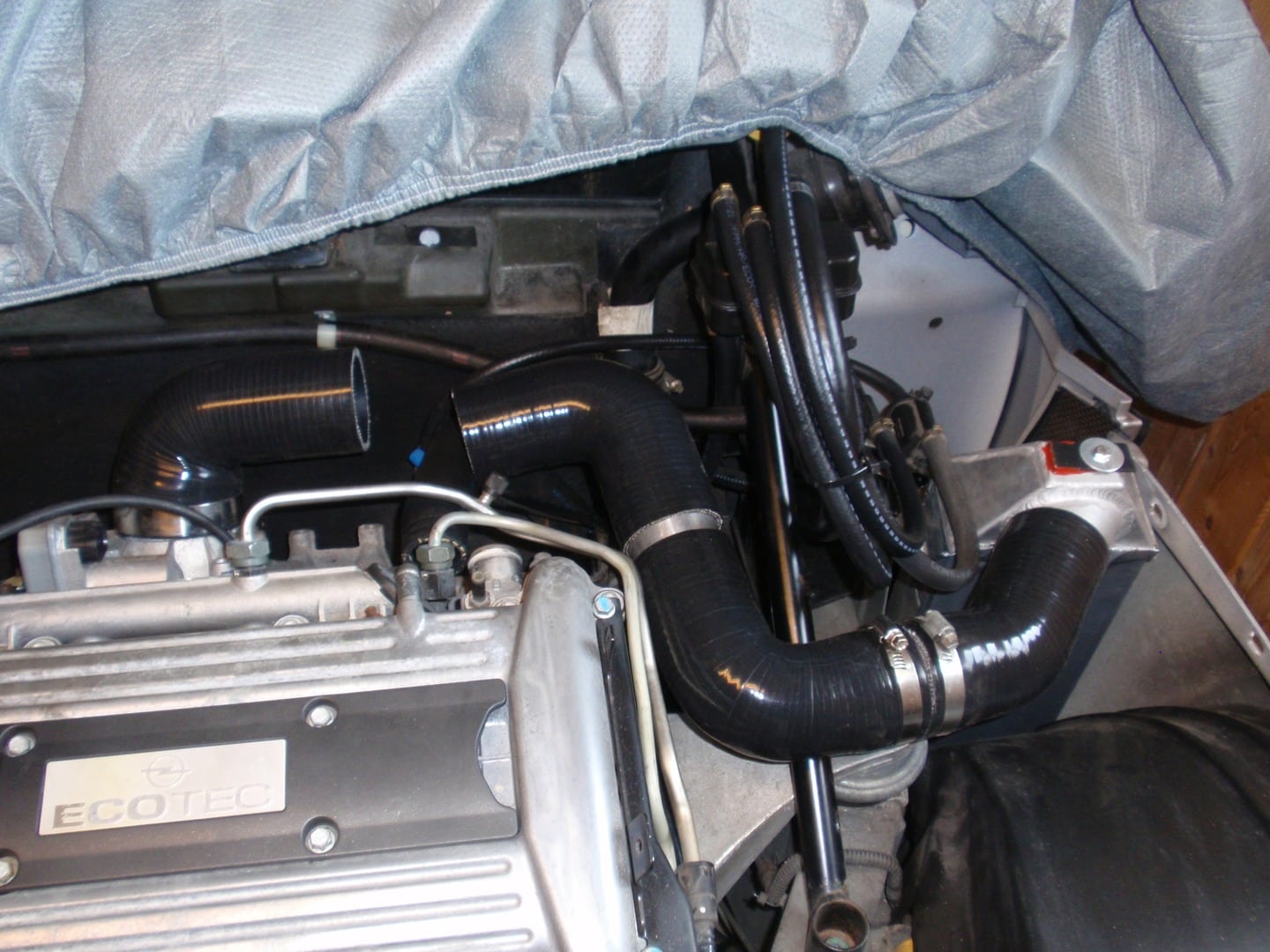

Working in the intercooler

... and the exhaust. Need some small stuff for it so will be done next week. A wideband and OBD-tuner and I think we're ready to roll.

#36

Posted 24 April 2015 - 11:21 PM

#37

Posted 24 April 2015 - 11:28 PM

looking good! ![]()

#38

Posted 26 April 2015 - 08:32 AM

For the map sensor I think you can take the rubber bung off, wrap some tale round the peg and then put the rubber bung back on. Still ghetto but looks OEM

#39

Posted 12 May 2015 - 08:41 PM

Little update.

Got myself OBD-tuner.

Put poly inserts in while we're there..

Weak moment of thinking I guess. Dipstick behind the IC piping. Still works but no perfect access...

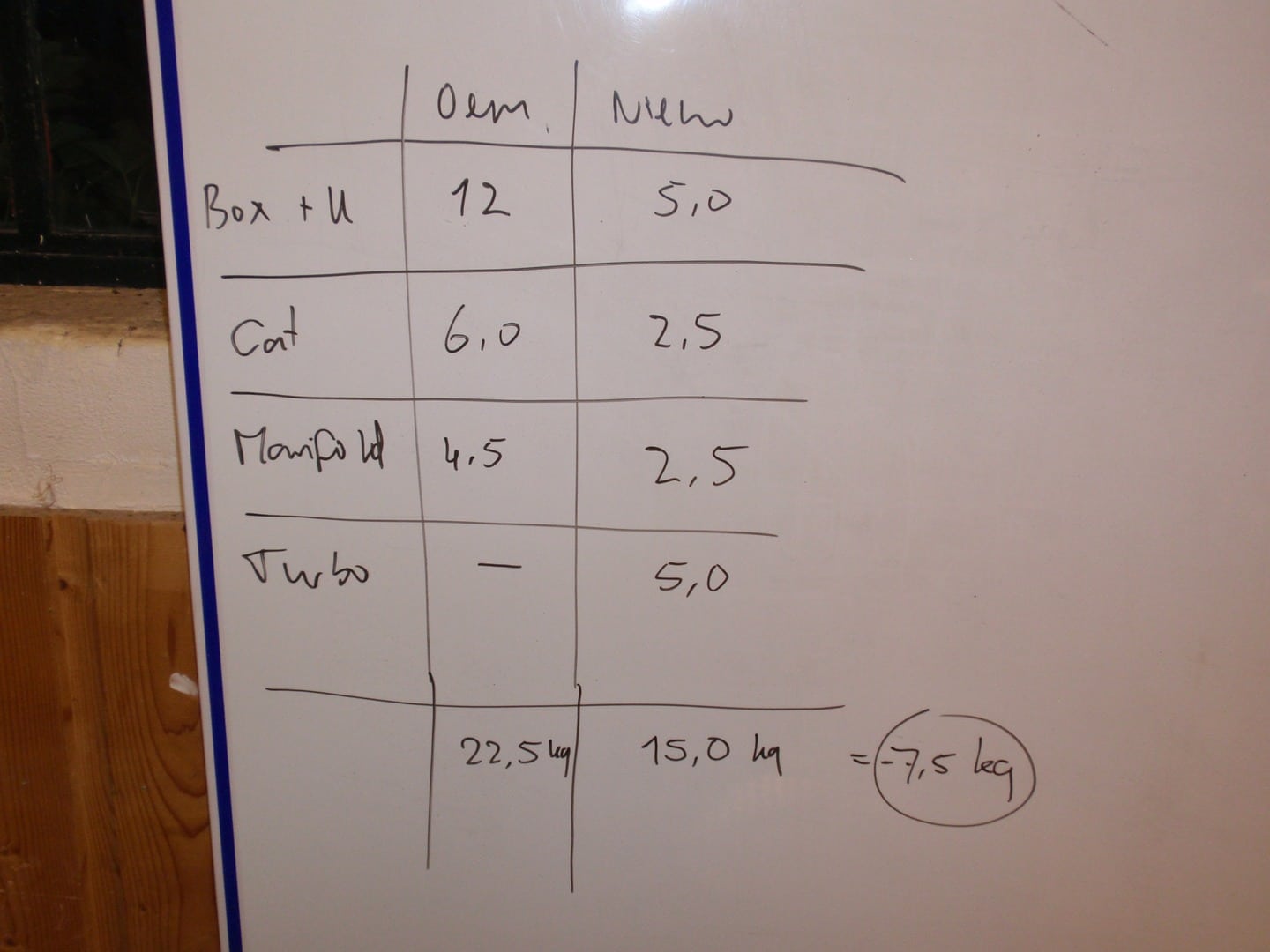

Did some weight meassuring: Minus 7,5 kg from oem exhaust (manifold till endtip) and that is inc. 5 kg heavy turbo! Pleased.

Have to finish exhaust and wideband and hope to start her up in two weeks.

#40

Posted 12 May 2015 - 09:23 PM

Nice progress on an interesting project ![]()

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users