Anybody Tried The Holley Hydramat For Fuel Starvation Issue?

#61

Posted 31 January 2017 - 10:07 PM

#62

Posted 31 January 2017 - 10:13 PM

it doesn't look a bad design internally wonder why we have problems

#63

Posted 31 January 2017 - 10:14 PM

i think the main reason we struggle is because it was designed to feed significantly less fuel that we are asking from it

considering we are doing quite well

#64

Posted 31 January 2017 - 10:24 PM

i wouldn't bother with the hydramat just stick a swirl pot in cheaper and proven

#65

Posted 01 February 2017 - 03:26 AM

If you've got a swirl pot already (I assume external with a secondary pump?) that is definitely the most robust solution. Thanks for the dimensions and photos of the OE tank. I'm looking for a cheap and easy fix to what is now an OE car.... I think I might have it (otherwise I'll go with one of the tried solutions). I did a few calculations:

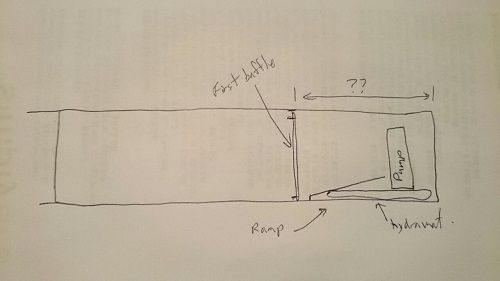

Searching the site I found SC consumption values of 35mpg on the road and 15 on the track. I took 15 and doubled it to 7.5 mpg for a factor of safety/excess. Then I went back to some old track videos, in my Cobalt turn 2 (the longest, highest g, ~150kph, left hand corner at my local track) took about 14 seconds from turn in to turn in at the next corner. So calculating at worst case I'd consume ~0.23L during that corner (assuming anything from the return side comes back to be used). If I look at the end of the tank as a 200mm x 200mm square floor in the end, I need a 5.7mm high ramp wall at level to hold enough fuel to make the corner... so if to the left of the pump I put a, lets say 10 or 20 mm high ramp to trap/contain enough fuel to make it around before the fuel comes the other way, with a hydra mat in the bottom under the ramp, I figure that should do it. Something like this:

This is kinda what I did in my old formula car (without the mat, just a very small cup at the bottom of the tank with ramps). So if there is enough room in the left side of the tank before the first baffle, I may try this. Anyone have an estimate of what that distance might be? and/or distance from the pump edge to the first baffle? The 3x15" hydramat should work here. I think the baffles alone in the OE tank are obviously not sufficient to hold much fuel in a corner for very long, but this should solve that.

BTW - Even without drain back under the ramp at worst I would trap a litre or two on a flat road... with a bit of motion or a small hole that should move over to the left driving down the road and provide good pick up even when cruising.

Well that's way to much math for one evening (hope I got it right), but if it fits, I may give this a shot for the cost of a 160$US mat and a bit of time and sheet metal, but probably not until the summer.

#67

Posted 01 February 2017 - 08:14 AM

#68

Posted 01 February 2017 - 08:49 AM

http://www.sector111...fle in tank.bmp

In a corner that tube works as a valve. ![]()

Edited by Exmantaa, 01 February 2017 - 08:50 AM.

#69

Posted 02 February 2017 - 12:55 AM

Thanks for the measurement. Looks like there is enough room to do a reasonable solution.... which is also the fundamental problem. With the distance from the fuel pickup to the first baffle at 200+mm, even with the tank half full, in a 1g corner there is enough room to take all the fuel away from the pickup pretty much instantly.

I was originally thinking the ramp or a one way door would be required, but with the baffles there I think the 3x15" hydra mat will solve 80% of the problem as it can get to the back lower corner of the "left hand chamber" where all the fuel should be hanging out (until the baffle drains). And that can all be done through the pump access hole. So I will order one of these: https://www.holley.c...ts/parts/16-111

To go to the next stage I think sealing the baffles and a one way trap door in the front part of the baffle would work well. There are lots of nice aluminum ones out there, but its best to be plastic to avoid galvanic corrosion, so one of these: http://fuelsafe.com/...td150-1445.html

It's not the ultimate solution of a swirl pot, but for the occasional track day, I think I can fit this without removing the tank and use most of the fuel without starvation.

Thanks for all the help and comments. I'll order the mat and have a shot at putting it in for the summer, if that's not enough I'll try the door. Unfortunately I filled the tank for winter storage so will want to burn that off before I tackle the installation.

FYI - If anyone is interested, here's a great article I found along the way on F1 tank design... lots of baffles and trap doors to contain the fuel low in the tank and keep the the CG from moving around. The video at the end shows a simulation with the effects of the solution (about 1min in).

https://scarbsf1.wor...1-fuel-system/

Here's an example that shows the violence of the fuel motion with baffles that are not great... https://www.youtube....h?v=yO1z7OKem-8

#70

Posted 02 February 2017 - 08:13 AM

#71

Posted 02 February 2017 - 01:45 PM

What a nice thread.

I don't have time for a long post but I can add a few thoughts that may help.

PROBLEM

This is simply the design of the car and the shape of the volume left for the tank. This is the worst possible shape and could only get worse if it were stretched sideways even made even more flatter.

As mentioned as anything under 75% capacity it is possible to remove the fuel from the pump pickup if the G is high enough.

This means you are only left with the reserve fuel in the pump unit (canister) and unfortunately the OE unit is an eductor design so this also stalls when out of fuel and will only restart once fuel has entered the canister by another method either through the valve in the base or by sloshing over the top.

SOLUTION

The best solution for this type of vehicle is a trapped tank with a very effective trap system, this means a trap that allows almost unrestricted flow into the trapped area but closes immediately as the flow tries to reverse. A simple, low mass flap is easily the best solution purely because it is so simple and effective.

The advantages over an external swirl pot (a trapped area is just an internal swirl pot) are: -

1. The pump remains in the fuel where it is designed to be, as the fuel is also used for cooling.

2. You only need a single pump which should be matched to the output +20% any more and the excess fuel which has just done a nice tour of the hot engine bay is returned to the tank to start another hot tour, not smart.

3. External pipes and unions are kept to a minimum and in a plastic car with a close fitting engine this will not be a surprise that it is not the best option.

4. Minor issues are the extra current draw of the second pump which should not even be needed and the general complexity of this solution.

So now we know what we want it is just a case of design, I already have a design from about 10 years ago that I was going to help make with PA before Wayne passed, I knew Wayne but no one else so it didn't happen, I did contact them twice last year but they never rang back.

The basics are : -

1. The trap has to work quickly and seal quickly.

2. The trap mounting plate must not interfere with the sender arm or anything else.

3. Any other traps need to be in the correct position to allow free flow into the trapped section.

4. The sender needs to give an accurate reading of the fuel quantity.

By combining these you can see it makes sense to remove the sender from the pump unit and place it in the main section of the tank with the float as close as possible to the centre of the tank in both horizontal planes. This is OK as long as you can still access the sender from the outside of the tank from the pump access hole. This can be achieved quite nicely in fact.

I will take a photo later of a trapped tank separation plate I knocked up years ago ......

The problem by the way with the proA tank is two fold, first the weird tube system does not flow well for the simple reason the area of the holes are too small and it also restricts flow by making the fuel change direction to go around the ball affair.

Secondly the baffle is not sealed, it has gaps around the edges and a hole at the bottom, I have no idea why. So fuel can leak back all the time.

Also because they have allowed for the float arm the area is too large and at 35% capacity and 1G it is possible to leave the pump out of the fuel again which is the only reason the trap was put in in the first place!

As for this bag design, I do like the idea but trying to retro fit it to an existing tank with all the baffles I'm not convinced,pretty sure the pickup can be sorted after a good think .....

0 user(s) are reading this topic

0 members, 0 guests, 0 anonymous users