Brake Lines - Mot Failure

#41

Posted 07 June 2017 - 12:46 PM

#42

Posted 07 June 2017 - 01:09 PM

Just had a quick look on SELOC and the S1 Elise has the brake lines running inside the cabin under a central divider. Is this a possible easier route (although it does involve dropping the tank)?

https://forums.seloc...ge=1#pid7113048

Same discussion here.

Central divider is no go due to the size of the wiring loom

Bummer. Thanks for thew suggestion, Chris ![]()

One thought. It's only the last 4 inches of pipe that need replacing (the part exposed by the side vents). How far can you get a flaring tool into the sill? You can then make up sill to rear caliper lines from copper.

That's a good idea ![]()

The tool suggestion for the job in another thread doesn't look that big - https://www.toolstod...laring-tool-kit

I guess positioning it and winding it down might be tricky. Also would cutting and cleaning up the brake line in situ be difficult? Oh for another access panel ![]()

#43

Posted 07 June 2017 - 01:29 PM

You've got quite a lot of room to play with when you take the rear wheel arches out.

Cutting the line should be easy with a pipe cutter (link this- https://tools.cromwe...ken5885450k.jpg) and won't require much clearance.

#44

Posted 07 June 2017 - 02:01 PM

Excellent. I'll have a look to see how far down the sill the cut would need to be and if my dainty lady hands can reach it ![]()

#45

Posted 07 June 2017 - 04:20 PM

#46

Posted 07 June 2017 - 05:14 PM

#47

Posted 07 June 2017 - 09:07 PM

With a bit of a tug the ear came off as the back is slotted ![]()

View from below where 7 meets 9 at rear

Intercooler ducting in ear (all plastic screws were mushed!)

View into opening

View down sill from back to front

Quickly managed to remove sill cover and get access to front of sill

View down sill from front to back

I can see now that with a bit of persuasion you could get a flexi pipe down the sill as the foam isn't particularly tight around the pipes. Gut feeling is that it might be easier to do that than try to cut and join the pipe near the corrosion point. As there's more space at the front might one option be to run flexi or hard pipe directly from the rear caliper (without the join at 7/9) and join at the front sill access?

#48

Posted 08 June 2017 - 10:15 PM

I had the exact same problem and used copper pipe from where it joins the flexi section at the back, making a join to the old pipe through the front access hole - as you suggest above. If you use hard pipe is has to be secured at regular intervals to prevent vibration fracture, which is difficult, I think a flexible line is probably the better way to do it

#49

Posted 09 June 2017 - 11:13 AM

I had the exact same problem and used copper pipe from where it joins the flexi section at the back, making a join to the old pipe through the front access hole - as you suggest above. If you use hard pipe is has to be secured at regular intervals to prevent vibration fracture, which is difficult, I think a flexible line is probably the better way to do it

Thanks zimmer. It's good to hear this approach was successful for you as well as tommobot ![]()

Still in two minds as to whether to replace the whole run with a braided line or use your approach.

Hoping to spend a bit of time this weekend seeing how easy it is to uncover the run from the ABS unit into the front sill. Front clam off perhaps? Initially I thought taking the dash top off might help but that looks too far back/on the wrong side of things. Has anyone got any pointers?

https://www.speedste...e Partially.pdf

Separation point must be made in vicinity of fastening point – clips, straps, etc.

Only one separation point per brake line is permitted.

Replacement is carried out from connection on corresponding wheel or from brake master cylinder to separation point.

Could an overzealous TIS reading MOT tester take this literally?!

#50

Posted 09 June 2017 - 11:29 AM

Perhaps spoke too soon. Is that the coolant pipe you can see in the top right hand side of the pic below?

#51

Posted 09 June 2017 - 11:49 AM

Yes,

#52

Posted 09 June 2017 - 01:01 PM

Thanks ![]()

#53

Posted 12 June 2017 - 10:52 AM

Dash off over the weekend and Haggi's pictures are making much more sense!

Driver's side dash corner

Foam removed showing coolant and brake pipes going down into the sill

Forward view with pipes going into bonnet section

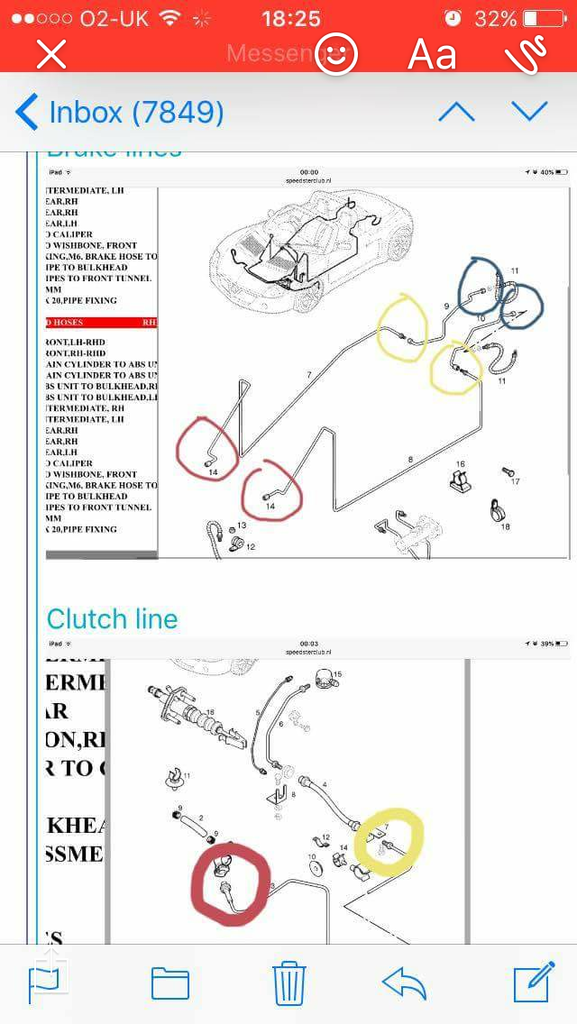

Decided to go with the Hel braided line as I'm not confident cutting and joining the sill hardline pipe. This arrived over the weekend and is just short of 3m. Haggi/ghand can you confirm what section(s) this replaces? According to the pic below pipe 7 is 250cm and pipe 9 is 68cm. Not sure how a 3m pipe can work ![]() Does it replace pipe 7 and the run to the ABS unit?

Does it replace pipe 7 and the run to the ABS unit?

Also did you find it necessary to increase the size of the hardline pipe hole where it goes from the dash into the front bonnet?

Thanks again for all your help ![]()

Edited by TheStotts, 12 June 2017 - 10:54 AM.

#54

Posted 12 June 2017 - 11:10 AM

#55

Posted 12 June 2017 - 11:25 AM

I have one of those, it requires a minimum radius of about six inches; depending on where the attempt at cutting was made I'm not convinced there is sufficient room, only trial and error will tell.You've got quite a lot of room to play with when you take the rear wheel arches out. Cutting the line should be easy with a pipe cutter (link this- https://tools.cromwe...ken5885450k.jpg) and won't require much clearance.

#56

Posted 12 June 2017 - 01:26 PM

I'm assuming the hel kit is just the piece through the sills where it joins from the two sections under the front clam and the other joins at the end of the sills towards the rear of the car. So red to yellow on my picture. When fitting it was really easy to do. I directed the hose through the sills at the rear both sides and then you have the cut out when you remove the plastic sill trims. You can then direct it through there under the dash and through the little hole while the hardlines are still in place. Once you have the hoses next to the joins you can undo and attach the new line saving brake fluid everywhere. After it all fitted he old lines can be cut up into pieces and pulled out through the different areas.

Brilliant - thanks for the advice ![]()

Can you recall having to increase the size of the hardline pipe hole where it goes from the dash into the front bonnet area?

Just had another look at Hel eBay listing and found the following:

This kit is to replace the aging hard lines which run down the sills of the car, with new HEL flexi lines. The new flexi lines replace the entire 3m long hard pipes on the car, and screw directly onto the existing brake flexi's.

This suggests a replacement for pipe 7 and 9 (not sure about 7 to ABS section) and explains why both ends of the flexi line have female connectors. 3m doesn't sound long enough given your figures so I'll confirm with Hel before starting the work ![]()

I have one of those, it requires a minimum radius of about six inches; depending on where the attempt at cutting was made I'm not convinced there is sufficient room, only trial and error will tell.You've got quite a lot of room to play with when you take the rear wheel arches out. Cutting the line should be easy with a pipe cutter (link this- https://tools.cromwe...ken5885450k.jpg) and won't require much clearance.

I imagine a skilled and experienced mechanic could succeed - as I am neither skilled nor experienced I've gone for the flexi option ![]()

#57

Posted 12 June 2017 - 09:49 PM

#58

Posted 13 June 2017 - 08:18 AM

Hell do a kit for this that goes from the rear calliper to the front connector. It's a 2 m long braided hose with the correct connectors on either end. My mate did mine and used a long rod to get through the packing stuff in the sill then fed the hose through. The other option is to feed a solid pipe through and join it to the existing pipe at the front of the sill that should still be good. You only need the wheel arch liners out.He did say it was a pita 😂 Mine burst and I lost all brakes and was very very lucky it wasn't a week later on the Hoon. Every VX need to be checked as the MOT do not look at them and without removing the undertray and looking at or feeling the pipe you have could have a disaster waiting to happen. Brilliant idea of Lotus/ Vauxhall to make fully hidden brake lines in stainless or copper oh hang on 😂😂😂

They connect to a long connector that sits on the tub frame, one either side and both the same. The pipe after that to the block should be fine, mine was like new.also worth mentioning there are two sizes of fittings on the ABS block, I think it's M14 for the passenger side and M10 for the driver side

Confirmation of the sections replaced - should have reread the thread more carefully ![]()

#59

Posted 13 June 2017 - 08:38 AM

Be warned - if you let all of the brake fluid drain out, it's an absolute PITA trying to bleed the brakes properly as they trap air in the calipers (search bleeding brakes) - if you can switch the lines quickly and keep some fluid in the brake fluid reservoir it might save you some grief.

Thanks for the tip ![]() Recall hours of "bleeding" fun when I changed the rear calipers

Recall hours of "bleeding" fun when I changed the rear calipers ![]()

I've purchased some M10 blanking plugs and plan to fill up the flexi pipe in advance of fitting and then do a quick swap over. Still concerned about how to get the flexi pipe through from the dash to the front connector while the hard brake line is still in place.

Anyone have experience of drilling through the black plastic section shown below?

Also there looks to be a pretty large gap underneath the packing stuff - would it be safe to run the line through a conduit here? Bit worried it would be exposed to damage from the underside. Any thoughts?

#60

Posted 13 June 2017 - 08:53 AM

Personally, i'd put the flexible cables in an outer sheath of something. It looks like Luke used firesleeve, which I think is a good idea given how close the brake lines are to a 90 deg. C coolant pipe. This will protect against any abrasive wear from rubbing against the bottom of the sill or anything else in there.

I wouldn't worry about damage from the underside. It's not a hard mounted pipe so will flex if you are unfortunate enough to damage your sill.

Finally, get a vacuum bleeder for your brakes. It's the only way I managed to clear air after changing my flexi lines.

Oh, black plastic: it's ABS plastic and really easy to drill. Use a stepped drill bit to avoid cracking

Edited by fezzasus, 13 June 2017 - 08:53 AM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users