Heat Shield Melting

#1

Posted 02 June 2008 - 07:57 AM

#2

Posted 02 June 2008 - 07:59 AM

#3

Posted 02 June 2008 - 08:14 AM

#4

Posted 02 June 2008 - 08:47 AM

i binned mine and glued a lot of this stuff (i got it cheaper on ebay) http://www.cbsonline...tmat-1567-p.asp

all over the boot section of the clam when i fitted my weapon R

#5

Posted 02 June 2008 - 09:48 AM

#6

Posted 02 June 2008 - 10:11 AM

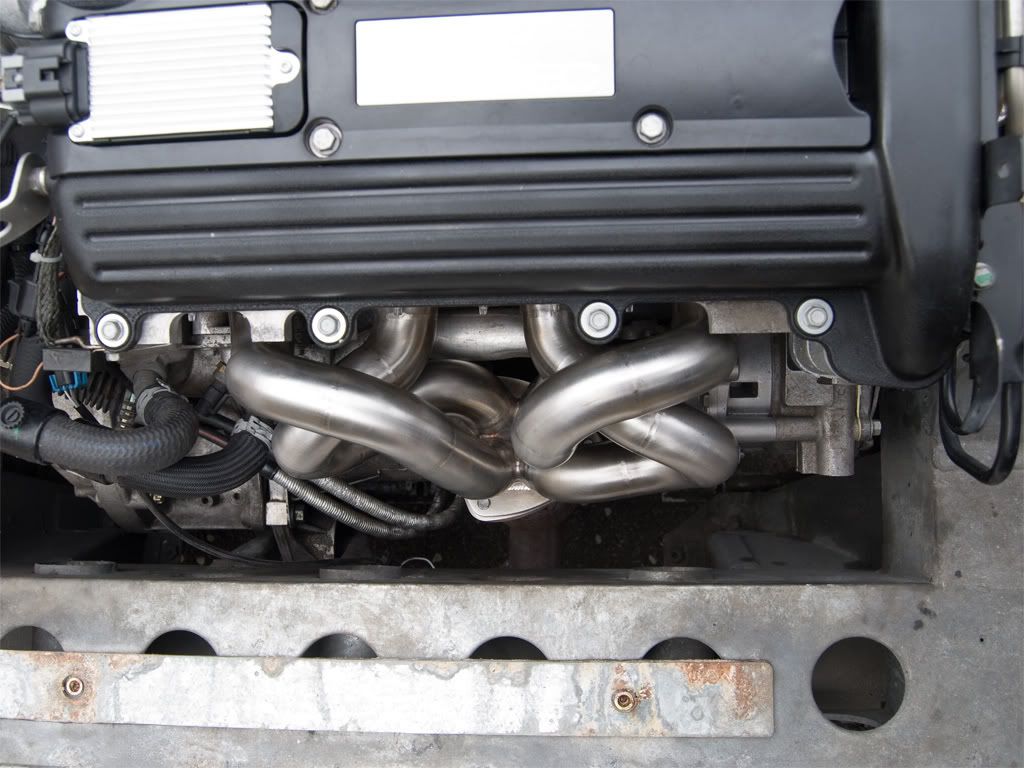

So this is the exhaust manifold presumably its tight packaging to fit in the space and there is not enough airflow / airgap . A shield should stop the radiated heat, and if possible you could bend / fold something similar to the turbo which as a chimney venting through the boot lid.

Try Merlin Motorsport ( based on site at Castle Combe )

http://www.merlinmot..._475/index.html

Edited by siztenboots, 02 June 2008 - 10:12 AM.

#7

Posted 02 June 2008 - 10:26 AM

thick rubber is probably there just to add further heat absorbtion

this is how mine looks

still gets warm in the boot where the cutout is tho

#8

Posted 02 June 2008 - 10:30 AM

Thanks Luna. Do you think that stuff would be ok, just stuck on the boot bulhead?

Why does the original have a thick rubber backing as well?

Martin s

Having looked at how techiboys fits on z22se there enough space to fasion a heat sheild from heat shield material like above and mount it from the same holes as the std heat sheild.

It's far better to have an air gap on either side of the heat shielding as the air acts as another layer of insulation.

Did TMS not notice the heat problems, while it doesn't need the clam cutting to fit thin walled stainless steel will conduct and get a lot hotter than a cast manifold and that has a heat sheild as std.

#9

Posted 02 June 2008 - 10:37 AM

I reckon I've got 1.5" clearance between the manifold and the heat shield, at it's closest point. I am a little concerned about the engine compartment cover and was thinking about fitting some form of shielding on the central GRP divider between the mesh vents. It looks like somewhere that might trap some of the rising heat.

It's hard to see the clearance from the angle of this picture, due to the uppermost piece of heatshield sagging a bit and overhanging the manifold .

#10

Posted 02 June 2008 - 10:44 AM

#11

Posted 02 June 2008 - 10:45 AM

#12

Posted 02 June 2008 - 10:52 AM

not that stuff tho, i got some offa ebay

and i used foil tape to seal the edges

#13

Posted 02 June 2008 - 11:04 AM

#14

Posted 02 June 2008 - 12:19 PM

Edited by Crimson_Killa, 02 June 2008 - 12:20 PM.

#15

Posted 02 June 2008 - 12:28 PM

this may sound a little

but i had the rear clam off to replace the manifold at the weekend and couldnt get the bolts off that hold the heat shield in place (let alone the manifold itself)

any tips?

edit to say i tried WD40 and the freeze release stuff!

Just took a bit of brute force when we first took it off a few weeks back. It came off really easily on Saturday when we binned the heatshield for the new manifold. The downpipe to manifold nuts where a bit harder though and took a bit of juice on the ratchet and extension bar.

#16

Posted 02 June 2008 - 12:42 PM

#17

Posted 02 June 2008 - 01:05 PM

having just looked at the tis,

are the top 2 bolts on the heat shield realy going into the cilinder head and not nuts on to captive bolts?

if this is so i might give it another go this weekend!

they are nuts on studs.

#18

Posted 02 June 2008 - 01:32 PM

#19

Posted 02 June 2008 - 01:46 PM

Sign up for a free Photobucket account, upload the picture to your account on that site and then copy the [IMG] link to your post(s) to display the picture. Failing that, email it to me at techieboy99-700@yahoo.co.uk and I'll do it as I'm a very interested party.

#20

Posted 02 June 2008 - 02:09 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users