Heat Shield Melting

#21

Posted 02 June 2008 - 02:35 PM

#22

Posted 02 June 2008 - 03:01 PM

#23

Posted 02 June 2008 - 03:06 PM

#24

Posted 02 June 2008 - 03:15 PM

#25

Posted 02 June 2008 - 03:23 PM

mmmm stinky

if i was to use the nimbus stuff id make it in one piece, then use bolts to fasten it to the clam using nuts as standoffs

wont be easy tho

If your using the Rigid Nimbus stuff it should be easier to make a heat sheild that bolts into the same holes as the original.

I'll draw one up later, it'll not be to scale but it'll give you an idea of what to do. Then mock it up using cardboard cut anf folded in the correct places and then use it as a template for the Nimbus material.

#26

Posted 02 June 2008 - 03:30 PM

#27

Posted 02 June 2008 - 03:30 PM

mmmm stinky

if i was to use the nimbus stuff id make it in one piece, then use bolts to fasten it to the clam using nuts as standoffs

wont be easy tho

If your using the Rigid Nimbus stuff it should be easier to make a heat sheild that bolts into the same holes as the original.

I'll draw one up later, it'll not be to scale but it'll give you an idea of what to do. Then mock it up using cardboard cut anf folded in the correct places and then use it as a template for the Nimbus material.

I'd certainly appreciate that Winstar. Top man.

#28

Posted 02 June 2008 - 03:33 PM

#29

Posted 02 June 2008 - 03:36 PM

#30

Posted 02 June 2008 - 03:41 PM

#31

Posted 02 June 2008 - 04:07 PM

#32

Posted 02 June 2008 - 06:17 PM

Now I understand. Didnt know that had one, as I never got my original manifold back for Thorneys.

I shall wait and see whats suggested by Winstar.

Martin s

yes there was a pressed aluminium one that was scured by to bolts, which also hold one of the the engine lifting eyes, into M8 (IIRC) threaded holed just below the rocker cover.

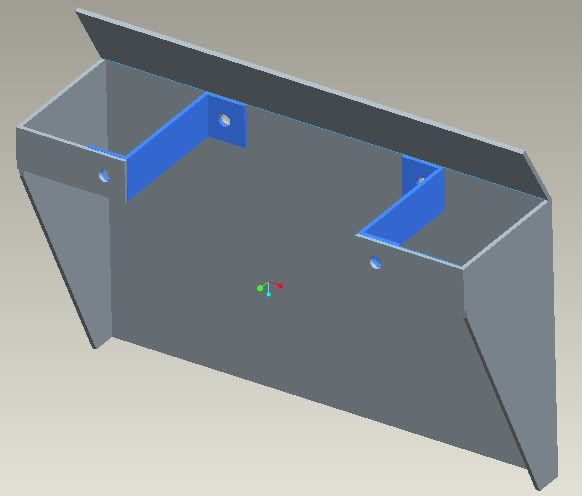

I was thinking something along these lines

As said it's not to scale but should give you an idea.

#33

Posted 02 June 2008 - 06:48 PM

#34

Posted 02 June 2008 - 07:09 PM

#35

Posted 02 June 2008 - 10:36 PM

#36

Posted 02 June 2008 - 11:41 PM

#37

Posted 03 June 2008 - 05:57 AM

#38

Posted 03 June 2008 - 07:00 AM

#39

Posted 03 June 2008 - 07:34 AM

#40

Posted 03 June 2008 - 07:58 AM

Martin, in this picture, the two yellow circles show the location of the upper mounting points. The red circle represents a lower fixing point that was part of the OEM manifold but which we no longer have. There were also two screws in the heat shield that tightened against the manifold at the the merge point to prevent rattles.

you beat me to it

That's a better photo, you shouldn't need the lower mounting point as the diagonal sections on the sides and the Z brackets should make it stiff enough not to need it, altough it may be better to leave more sheiding on the side to cover coolant pipes on the left.

As for bolt you'll need 2 that fit in the existing holes then some M5 or M6 stainless nuts and bolts to secure the Z bracket.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users