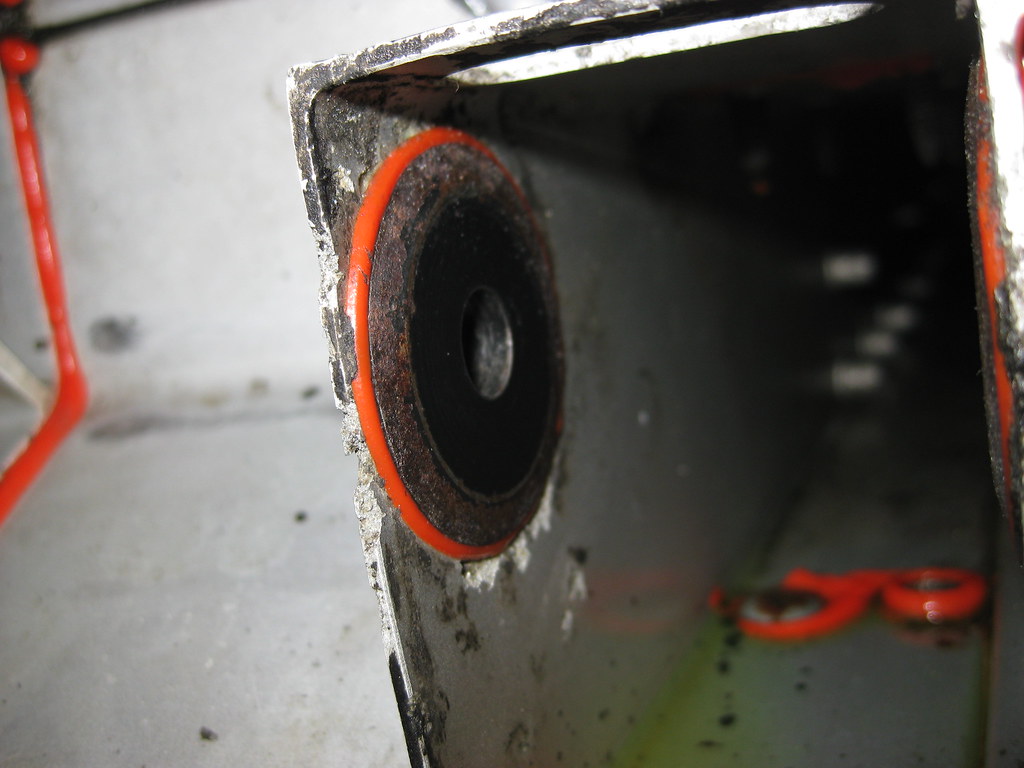

must agree.i read the thread on seloc and thought then,unrepairable,new chassis.hmmmm!!!

Why cant you fix it? Why cant you just weld/ bolt / bond (you catch my drift) A completely new mounting point in??? To say something cant be fixed seems a bit daft to me....

Its corroded, so cut it out and weld or bolt a new plate in and make it stronger? Am I being stupid here? Just seems common sense to me? Surely you could fix it, Yeh, it would not look the same, but it would do the job???

Yeh no chance in hell I would be scrapping my car for that little washer problem

I would have something else welded and bolted back in its place, It might not look pretty and it may weigh more, but im sure I would get it done....

Edited by chrisgold, 09 January 2012 - 07:06 PM.