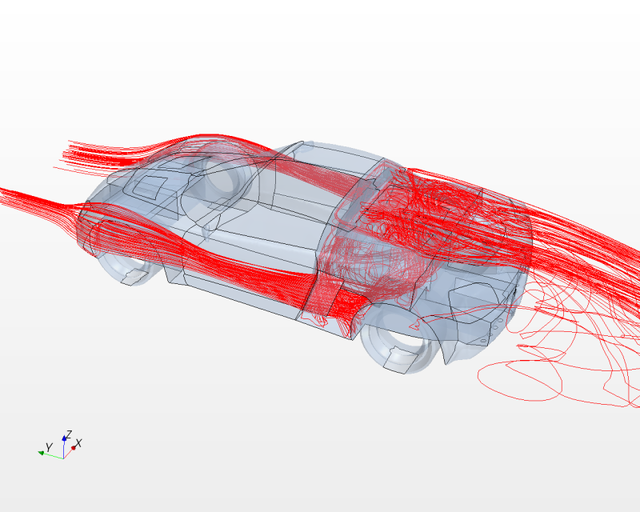

Just realised anwersing the SC CC post, I got my efficiency term upside down it actually needs an air velicity of 92mph through the ear!it depends on what you want the IC will be good enough for stg 4 on the road but I have my doubts that you can get enough air flow for hard track work no matter how efficent the core is. If you do the numbers to drop the charge for 300bhp from 110'C to 40'C will reject 17.6kW. With a 90% effictive IC, an air temp of 20'C and assuming the open area of the ear is 0.03m2 then the air through it need to be 60 mph. Which given the dirty air the ear gets it will need the car to be traveling much faster to get that flow and thats before you even get to where the 17.6kW of heat goes.

Larger Intercooler V's Charge Cooler

#61

Posted 12 June 2013 - 11:23 AM

#62

Posted 12 June 2013 - 11:56 AM

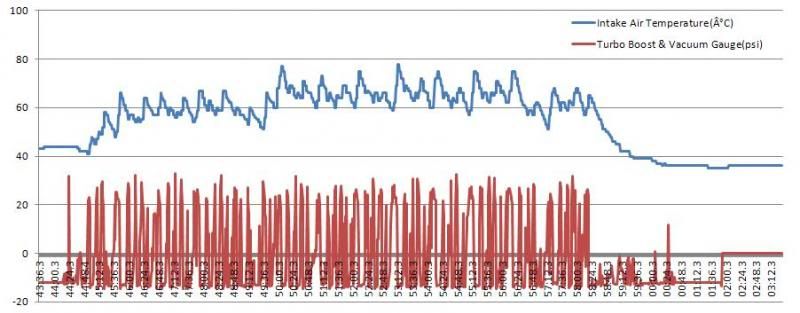

A bit hot, not too bad. You will be getting some retard over 50-55 degrees from what i've heard.

Lots of boost...basically 2 bar peak.

not sure you really want boost spikes at 30+psi , normally the map should limit this to ~20psi .

#63

Posted 12 June 2013 - 01:54 PM

below are the numbers from the model, the blockage of the IC would reduce the flow rate through there quite a lot how much would depend on the design and how much actually went through the cooler and how much could leak around.That's interesting thanks.

I used to be in auto engineering too (engine design / FEA then ran an engineering consultancy for a few years).

I assume the intercooler drag would make a big difference to the mass air flow through the duct and through the intercooler - do you have a view?

I've worked in FEA and CFD since graduating 12 years ago I did do automotive but I sold out and have done oil and gas for the last 4.With ears

Ear flow rate - 0.66 kg/s

#64

Posted 12 June 2013 - 02:27 PM

With thanks to Winstar my charge intake temps have dropped from nearly 100degrees constant to 45 peak and astonishingly quick recovery rates.

Did I miss a thread / link? I know you upped the coolant flow with a massive pump and big dia waterhoses.

Chargecooling is now on top of our list since we measured 87*C IAT's on the Zolder circuit with a Harrop charger and PA cooler up front... (And that was not full beans out and the big 3.15" SC puley.)

Next will be some extensive in & out water T-measurements, but most likely this will show that the coolant water only gets luke warm after the Laminova's.

#65

Posted 12 June 2013 - 02:29 PM

Winstar (if you can be arsed or know already) how much more effective is the exige style roof scoop that feeds down to the air to air IC.

I know the front of the exige is different to the vx and so airflow to the scoop entrance will be slightly different but is it that much more effective?

Lotus, ESmotorsport (the pic i posted) Newey and the Red Bull exige all think/know it is.

#66

Posted 12 June 2013 - 03:32 PM

Roof scoop is a terrible place to get an air feed from... The air going over the roof is straight out of the front rads and pre-heated.

#68

Posted 12 June 2013 - 10:19 PM

The other thing that's interesting is sizing of the CC rad at the front.

For a race duty cycle (high load a lot of the time) a large rad is obviously needed - I would expect (and obviously haven't done the sums) that the system would reach quasi steady-state fairly quickly,. limited by the rad's ability to reject heat.

For a road duty cycle load is going to be far more intermittent; the system probably won't ever reach it's peak quasi steady state temp as you won't be able to sustain continuous high loads for long enough to get there. So provided there's enough water in the system the CC rad can be smaller.

I like the idea of things being easy - like a CC rad small enough to fit without removing the front clam...

Or one which could live in the ear on the left hand side?

#69

Posted 13 June 2013 - 05:59 AM

#70

Posted 13 June 2013 - 08:21 AM

#71

Posted 13 June 2013 - 08:53 AM

Thought the whole point of CC was so you could have a bigger cross-sectional area where air passed through it? So to use the ear you might as well just have an intercooler?

correct - but I'm talking about a CC as well as the existing IC.

Or two ICs - but then the inlet tract gets a bit longer.

#72

Posted 13 June 2013 - 08:54 AM

Probably need the ignition charted as well, as that's what the ECU will have backed off when/if the heat got too much.

I re checked (hoping I dont need to go specsavers) but couldn't spot [color=rgb(40,40,40);font-family:helvetica, arial, sans-serif;]ignition status listed for the Torque app (well not showing output at least)[/color]

#73

Posted 13 June 2013 - 10:53 AM

ign timing is there , and I have it working on the scanguage too , now if torque could read the knock sensor and datalog it

#74

Posted 13 June 2013 - 10:56 AM

sorry Mark, was that torque you used to log the boost TMAP sensor as that usually doesn't work , so would be handy to know

#75

Posted 13 June 2013 - 01:23 PM

I used a obd2 Bluetooth via a HTC running Torque Pro I don't think my car boosts to 30psi... As never seen anything over 25psi on the gauge in the cockpitsorry Mark, was that torque you used to log the boost TMAP sensor as that usually doesn't work , so would be handy to know

Edited by mbes2, 13 June 2013 - 01:24 PM.

#76

Posted 13 June 2013 - 01:46 PM

#77

Posted 13 June 2013 - 02:06 PM

#78

Posted 13 June 2013 - 08:06 PM

#79

Posted 13 June 2013 - 08:10 PM

Yes - this is it, i'd be more not less tempted by the IC option having seen that. I'd have put a tenner on IAT over 100degrees peak.

Its certainly true that there is room for improvement, but i bet the stock PA system (certainly pre revision) is not miles different.

Of course what really WOULD benefit the forum is someone being brave enough to find that out! /Nudge.

Thermal management is a problem all of us (esp forced induction) share.

#80

Posted 13 June 2013 - 08:23 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users