Vx220 Vag Conversion - Dg Starts Something Different

#101

Posted 17 January 2012 - 03:13 PM

#102

Posted 19 January 2012 - 10:55 AM

#103

Posted 19 January 2012 - 11:38 AM

So does the VAG lump have an LSD?

Only if you put one in steve but this one will

The S3 setup uses the 4wd but this is out of the edition 30 so fwd and any of the 6speed 2wd boxes fit as I dont need speed signals etc which you do in the canbus / vag stuff

DG

#104

Posted 02 February 2012 - 10:55 AM

#105

Posted 02 February 2012 - 11:03 AM

#106

Posted 02 February 2012 - 11:30 AM

#107

Posted 02 February 2012 - 11:47 AM

Edited by SteveA, 02 February 2012 - 11:48 AM.

#108

Posted 02 February 2012 - 12:31 PM

I do think a lightweight small v8 with a decent power output would make the vx a bit of a supercar (noise content and looks

) but for power the 2.0 tfsi can make the same with ease and lighter and less work to fit

but if you're using that logic then there's no point changing either of the original engines

Edited by Winstar, 02 February 2012 - 12:31 PM.

#109

Posted 02 February 2012 - 12:37 PM

#110

Posted 02 February 2012 - 12:39 PM

I do think a lightweight small v8 with a decent power output would make the vx a bit of a supercar (noise content and looks) but for power the 2.0 tfsi can make the same with ease and lighter and less work to fit

but if you're using that logic then there's no point changing either of the original engines

I have not in the standalone garrett conversion

May have an option of buying the new RS3 engine which if I can get at teh right price and steal the money off sarah be my own future conversion - prob drop it in the skoda for now lol

DG

#111

Posted 02 February 2012 - 12:51 PM

The DSG box is HEAVY! the newer dry cutch 7 speed item would be better

Just thnking that sequential gears or even paddle shift would be ace on a track car. I like the idea of shifting in tenths of seconds.

Edited by SteveA, 02 February 2012 - 12:51 PM.

#112

Posted 02 February 2012 - 01:00 PM

#113

Posted 09 February 2012 - 03:31 PM

Well as per previous update this is version 3 top engine side mount bracket after my OCD took over and made 2 revisions to the engine location lol

Will get a pic of it fitted but seems the extra few hrs of triple checking and measuring means it fits like a glove......never doubted my drawing for a second lol

Hoping the weather eases off this weekend to do more and hopefully drop zacs car off to the RR

DG

Not this is done I can triple check the box mount which it a bit less wrok and finish the bottom bracket which needs to have the others finished 1st

#114

Posted 13 February 2012 - 09:25 AM

Some more pictures

Drivers side top mount had further work to counter sink the bolt not shown in picture and the gearbox adaptor plate has been drilled, tapped and the spacers redone with added 5mm as required to make the spirit level happy

Will get some of the finished pics up this week as it was late when fitted last night and too clold to get camera out lol

So finish bottom mount this week and can get started with driveshafts

DG

#115

Posted 13 February 2012 - 09:27 AM

#116

Posted 13 February 2012 - 09:51 AM

DG

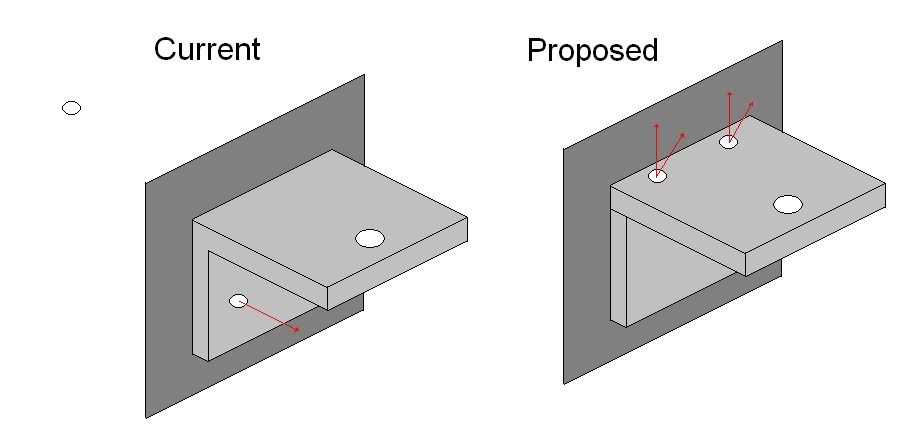

The sheer on those two bolts looks pretty unkind? I think i'd want some form of triangulation, or at least some form of mounting in the horizontal plane rather than the vertical.

Great project though.

#117

Posted 13 February 2012 - 10:07 AM

Edited by Duncan VXR, 13 February 2012 - 10:08 AM.

#118

Posted 13 February 2012 - 10:30 AM

#119

Posted 13 February 2012 - 10:54 AM

#120

Posted 13 February 2012 - 11:03 AM

The stresses on the bolts in that mounting arrangement shouldn't be much different to the original mounting approach.

Yes it is, its completely different.

On the standard engine,. the mounting is bolted on the engine on the horizontal plane. so the bolts are stressed along their length (which is what they are designed to do). on the above configuration there is now a sheer stress across the bolt, which they don't like at all. On the standard arrangement you also benifit from having a greater surface contact area which helps.

I can work out the stresses and strains if i had a few measurements, the rough weight of the engine, and the relative locations of the mounts to COG. Big enough bolts may take it, its just not very good practice imo. This might illustrate it better.

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users