Volvo T5 Engine Transplant

#141

Posted 19 February 2015 - 07:59 PM

#142

Posted 19 February 2015 - 09:39 PM

Edited by vxt5, 19 February 2015 - 09:43 PM.

#144

Posted 20 February 2015 - 07:06 AM

The alignment between the gearbox and hub looks quite out of line (horizontally, as well as the typical vertical articulation)... Will that not induce additional heat into the CV joints and cause premature fatigue?

Can be an issue, but sometime you simply have to work within the packaging constraints and 'suck it up'.

Using high-spec greases for the joints can at least help. Eg. something like NEO HPCC1 CV grease for ball-CV's and OKS422 grease for tripod joints. (never use CV grease in Tripods.. It kills 'em rapid as it contains solids that gunk up the needle-bearings in tripod bearings..)

Engine could perhaps be moved back a little to get a better horizontal driveshaft angle, but then there may be a clash with the exhaust/turbo towards the subframe or boot so you trade one issue for another.

If it turns out to be an issue (eg. going through CV's fast) then another option may be to see if the engine can be tilted a little so the diff housing is moved further back into the subframe and the top of the engine remains in the original spot. Needs some care to make sure that no oil starts pooling/collecting in the head and such though.

Bye, Arno.

#146

Posted 20 February 2015 - 06:33 PM

Looks like there is a butterfly that either uses both silencers or none at all... bet that's loud in "none at all" mode ![]()

#147

Posted 20 February 2015 - 08:02 PM

The valve I have is vacuum operated one as the electronic type seem to brake under the high temperatures theyre operating in.....although the vacuum will be controled by a switch via a solenoid therefore being able to turn it off and on as I please

That lookswill it be electrically operated? so switch in the cabin?

you going to make a kit for anyone who wants to follow you

#148

Posted 20 February 2015 - 08:08 PM

Still have the turbo to muffle itLooks like there is a butterfly that either uses both silencers or none at all... bet that's loud in "none at all" mode

Edited by vxt5, 20 February 2015 - 08:10 PM.

#149

Posted 20 February 2015 - 08:32 PM

Thanks for the advice Arno. I would have used cv grease at the cv end and tripod bearing end (cringe). For the cv end im thinking this should be fine?? http://m.ebay.com/it...268?_mwBanner=1 Also I may decide to put some temp strips on or as near to the joints as possible to check for operating temps whilst running. This should tell me if im running a bit hot on the joints and if im in the right ballpark with the selected grease.Can be an issue, but sometime you simply have to work within the packaging constraints and 'suck it up'. Using high-spec greases for the joints can at least help. Eg. something like NEO HPCC1 CV grease for ball-CV's and OKS422 grease for tripod joints. (never use CV grease in Tripods.. It kills 'em rapid as it contains solids that gunk up the needle-bearings in tripod bearings..) Engine could perhaps be moved back a little to get a better horizontal driveshaft angle, but then there may be a clash with the exhaust/turbo towards the subframe or boot so you trade one issue for another. If it turns out to be an issue (eg. going through CV's fast) then another option may be to see if the engine can be tilted a little so the diff housing is moved further back into the subframe and the top of the engine remains in the original spot. Needs some care to make sure that no oil starts pooling/collecting in the head and such though. Bye, Arno.The alignment between the gearbox and hub looks quite out of line (horizontally, as well as the typical vertical articulation)... Will that not induce additional heat into the CV joints and cause premature fatigue?

#150

Posted 20 February 2015 - 08:49 PM

Red line stuff is not bad and should do OK, but if you do find that you're burning out outer CV's then the NEO stuff does give more leeway as far as being able to push it further in the same setup.. It's expensive though!

For the inner tripod you can also use GKN tripode grease:

https://www.merlinmo...-gm-gkn-ms9u025

It's also good stuff and will work fine as long as it's not over-heated too much.

The OKS422 grease is more resilient, but again it's quite expensive goop...

Still.. Sometimes there's little other option if, in such a situation, you may not be able to change much on the shaft angles and have to work with them 'as is'.

Only thing you can then do is find the most durable joints possible, keep 'em cool(ed) and stick the best grease in them to make them last the longest.

Bye, Arno.

#151

Posted 19 March 2015 - 08:55 PM

IMG-20150316-WA0003.jpg 44.44KB

46 downloads

So we started to make a connecting pipe (for not of a better word) to fit and hold the throttle body and manifold together.

Heres the flange for the manifold side made up and ready to be welded

IMG-20150316-WA0003.jpg 44.44KB

46 downloads

So we started to make a connecting pipe (for not of a better word) to fit and hold the throttle body and manifold together.

Heres the flange for the manifold side made up and ready to be welded

IMG-20150317-WA0010.jpg 73.55KB

46 downloads

We then made the flange for the throttlebody side. Tacked in in position and welded them. This is the finished article.

IMG-20150317-WA0010.jpg 73.55KB

46 downloads

We then made the flange for the throttlebody side. Tacked in in position and welded them. This is the finished article.

IMG-20150318-WA0002.jpg 116.46KB

47 downloads

And in position

IMG-20150318-WA0002.jpg 116.46KB

47 downloads

And in position

IMG-20150317-WA0014.jpg 118.37KB

47 downloads

IMG-20150317-WA0014.jpg 118.37KB

47 downloads

IMG-20150317-WA0017.jpg 84.35KB

47 downloads

Now I just need to patch up the bulkhead and give it all a quick tidy up. Luckily enough the pipe doesnt protrude far enough to foul on the interior bulkhead panel so I wont have to do anything to this.

IMG-20150317-WA0017.jpg 84.35KB

47 downloads

Now I just need to patch up the bulkhead and give it all a quick tidy up. Luckily enough the pipe doesnt protrude far enough to foul on the interior bulkhead panel so I wont have to do anything to this.

#152

Posted 19 March 2015 - 09:44 PM

This is how it looked before being attacked. Minus the long grey arm you can see in the pic

#153

Posted 19 March 2015 - 10:17 PM

The other selector arm (front/back) was fabricated onto the other side of its pivoting point onthe me hanism to reverse it and the original volvo cable retaining frame was reconfigured to accept new positioning of the vx cables.

Completed selectors

#154

Posted 20 March 2015 - 06:06 AM

Smart work on the gearbox cables,

You make it look simple. Impressive.

#155

Posted 29 March 2015 - 07:32 PM

Edited by Nev, 29 March 2015 - 07:33 PM.

#156

Posted 03 April 2015 - 07:19 AM

#157

Posted 06 April 2015 - 09:49 PM

Chris Randal (Lotus cup etc) rated the Syvecs ECU very highly, it certainly has all the bells and whistles on it.

I have Adaptronic 440 on mine, it's a lot cheaper than Syvecs and my maps (I have 2) are excellent. The guy who fitted and mapped it for me is excellent too (and I don't say that lightly).

Edited by Nev, 06 April 2015 - 09:52 PM.

#158

Posted 26 April 2015 - 08:21 PM

The syvecs s6gp, this should make life alot easier and give me lots of goodies to play with once its all set up. Much more control over the original (standard) set up i was previously thinking about using.... although im sure it wont come without any headaches lol.

we decided to start on the exhaust also.... weve been stalled for a while due to waiting for the turbo to downpipe flange to be machined but decided to start on the rear of the exhaust and work our way back. I know this is probably not the conventional way to do it but needs must if i want to get all the fabrication work on the car complete...

Rushed into buying lots of exhaust parts early in the project which weve found to be redundant really so rather than forking out more and more were usinv the straight 3" pipe ive got to make the bends we want if we find these are somewhat restrictive or a problem in the future we can always copy our exhaust using mandrels etc.

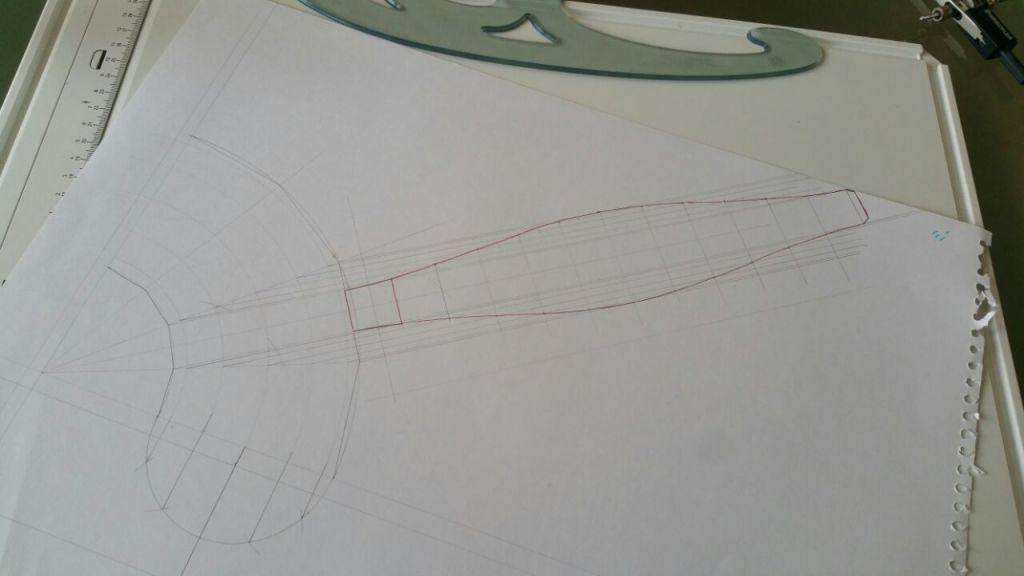

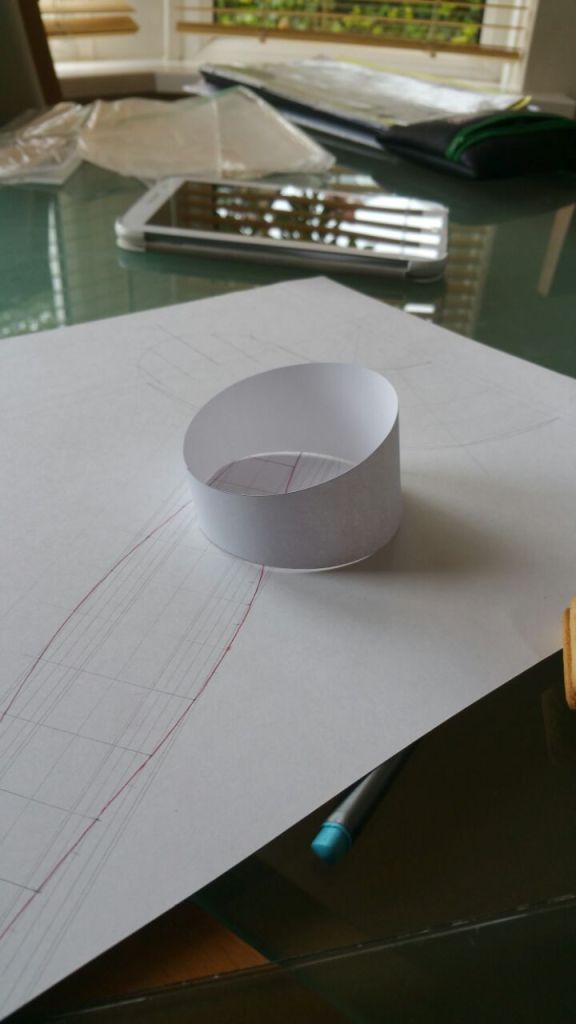

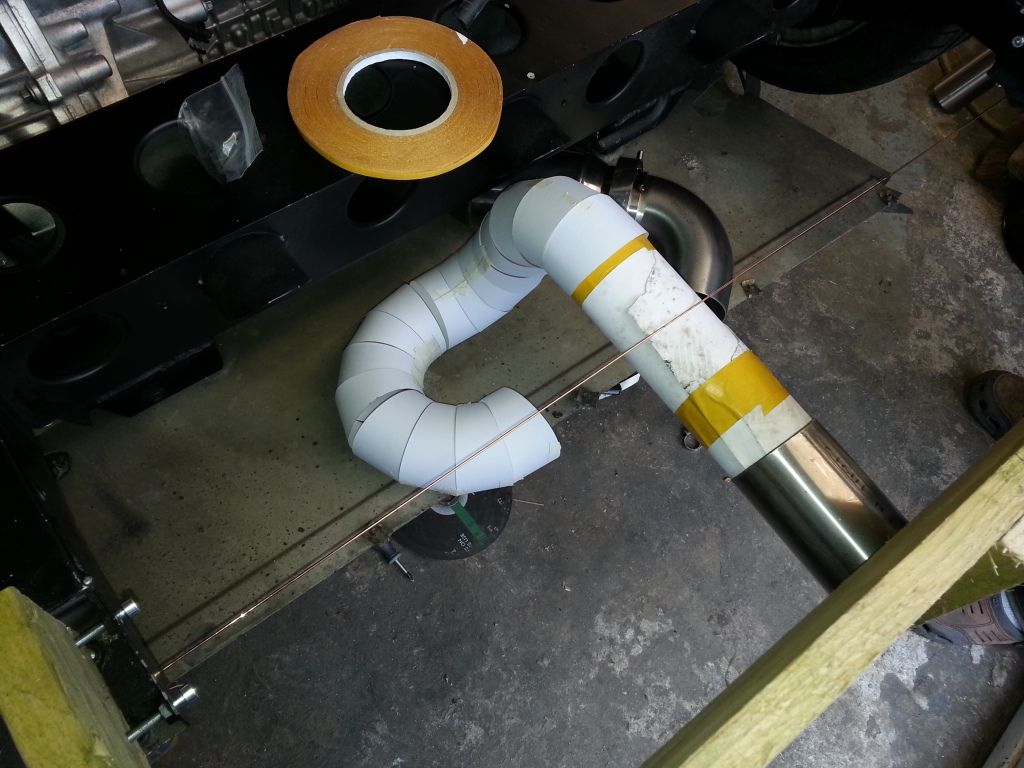

first off we made paper templates of the sections we were going to use. Decided to start off with 4 segment 90° bends for speed and ease of fabrication even though Matt was nagging me to use 8 segment 90s in titanium lol.

We made a wooden frame on the back of the car to mark where we wanted the exhaust to end and attached the undertray to see how much room we had. I didnt take any pics of this but you can see it in the pictures where we mocked the segmented bends and post cat exhaust up with the paper templates.

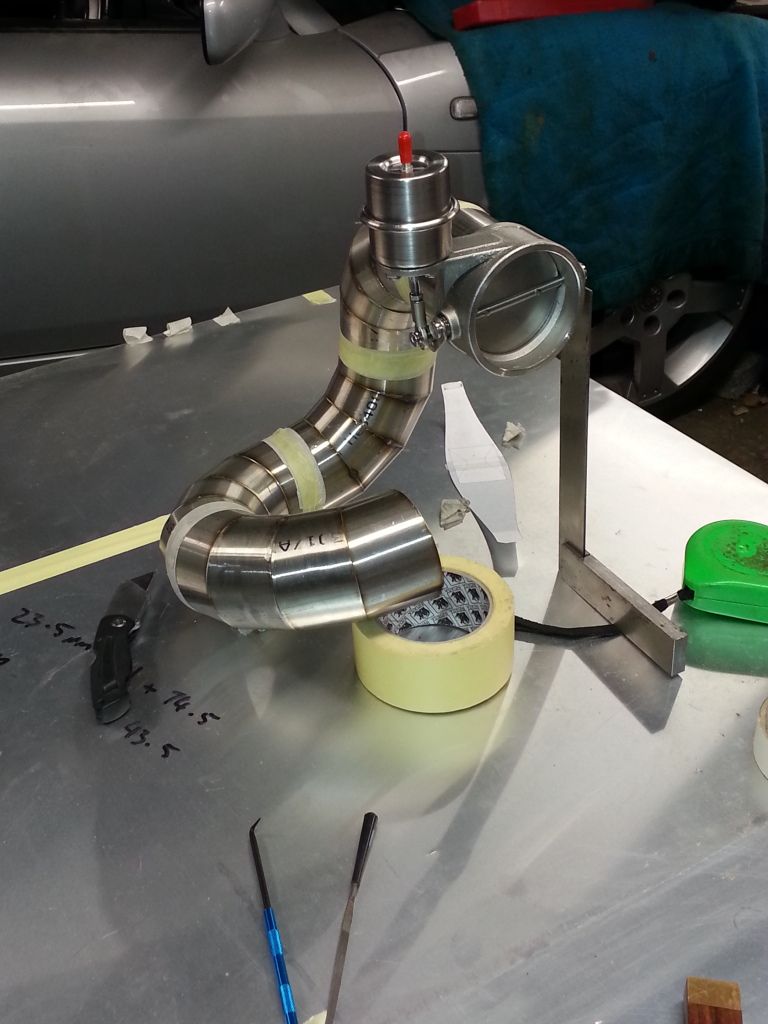

Once we got a rough idea of what we wanted the next stage was to fabricate some out of 3" t304 tube.

Tacking these together and making templates for the 2.25" pipe to go on the silencers ive bought is as far as weve got.

Some pics of this...

#159

Posted 26 April 2015 - 08:25 PM

#160

Posted 26 April 2015 - 09:20 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users