ponies/vodka lolno 5th october 2009!! for a few more ponies

My Little Adventures...

#281

Posted 27 August 2009 - 05:14 PM

#282

Posted 03 September 2009 - 06:34 PM

thanks again cliffie

#283

Posted 03 September 2009 - 06:39 PM

#284

Posted 03 September 2009 - 06:40 PM

Edited by joe_589, 03 September 2009 - 06:41 PM.

#285

Posted 03 September 2009 - 06:43 PM

*Ok, so maybe not quite that simple

#286

Posted 03 September 2009 - 06:44 PM

#287

Posted 03 September 2009 - 06:58 PM

#288

Posted 03 September 2009 - 08:40 PM

#289

Posted 12 September 2009 - 04:50 PM

#290

Posted 12 September 2009 - 05:06 PM

progress so far with the swirl pot and pump

nice braket lol

#291

Posted 12 September 2009 - 05:07 PM

#292

Posted 12 September 2009 - 05:10 PM

need new fixing

its work in progress! got to make a template before a nice shiny 1 can be made

#293

Posted 12 September 2009 - 05:11 PM

#294

Posted 12 September 2009 - 05:18 PM

#295

Posted 12 September 2009 - 05:20 PM

#296

Posted 12 September 2009 - 05:24 PM

lol what advice you want?

a new set of stainless still fittings lol or gold plated be ok

#297

Posted 12 September 2009 - 05:40 PM

#298

Posted 14 September 2009 - 04:22 PM

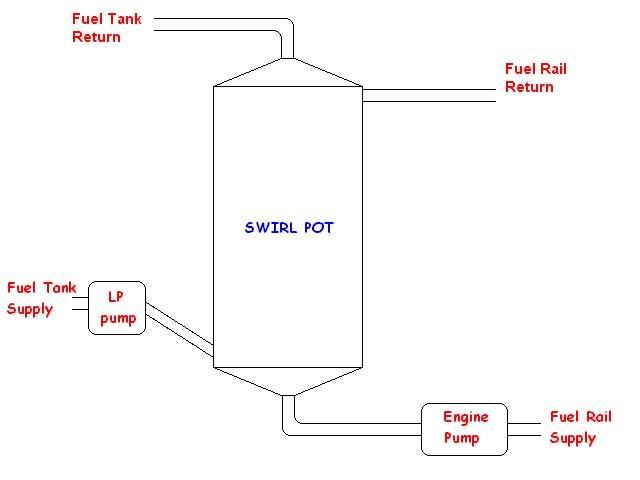

I may be completely wrong here, but I presume you want to use the new pump as the OEM one isn't man enough for the power level you want, so you plan to:

OEM Fuel Pump > Fills Swirl Pot > Bosch Pump > Fuel Rail and/or Return to Tank

But the limiting factor is the capacity of the swirl pot, which is essentially simply acting as a buffer tank

Trouble is on long straights (esp the motorway) there's a good chance you'll empty the swirl pot if the OEM pump can't keep up (which you've already shown it can't) in which case the new pump may suffer together with your fueling

I could however have this completely wrong, as the OEM pump will no longer be supplying a high pressure line (does it in stock form), instead it will be open end

For the swirl pot I'd imagine you want a feed in from the OEM pump, a mid point take-off for return to tank and a bottom take off for the Bosch pump

The best solution would be to simply put a line into the existing tank (keeping the OEM setup for level indication) and feeding that straight to the Bosch pump, then use the stock return to tank line

But as I said, I could be completely wrong

No it doesn't work like that. The operation of a pump follows a curve*, like a single speed line on a compressor map, that means that the less pressure head it has to provide the more flow it will give. Exactly how much will depend on the type of pump and specific design, also on top of this depending on how the motor to the pump is controlled as the load is reduced it could also spin faster so providing even more volume flow.

edit like thisclicky

Edited by Winstar, 14 September 2009 - 04:26 PM.

#299

Posted 17 September 2009 - 10:04 PM

#300

Posted 18 September 2009 - 01:18 PM

Also it will go

tank pump -> swirl pot -> high pressure pump -> rail/reg -> return to swirl pot. the Swirl pot will take its highest outlet to the tank return.

So the pot should have 4 connections to it. atleast one low one and then atleast 2 high ones and the other, well that isnt mega fussy where that is

this is the diagram i have been following:

and this is the swirl pot i have, it is a direct match to the diagram

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users